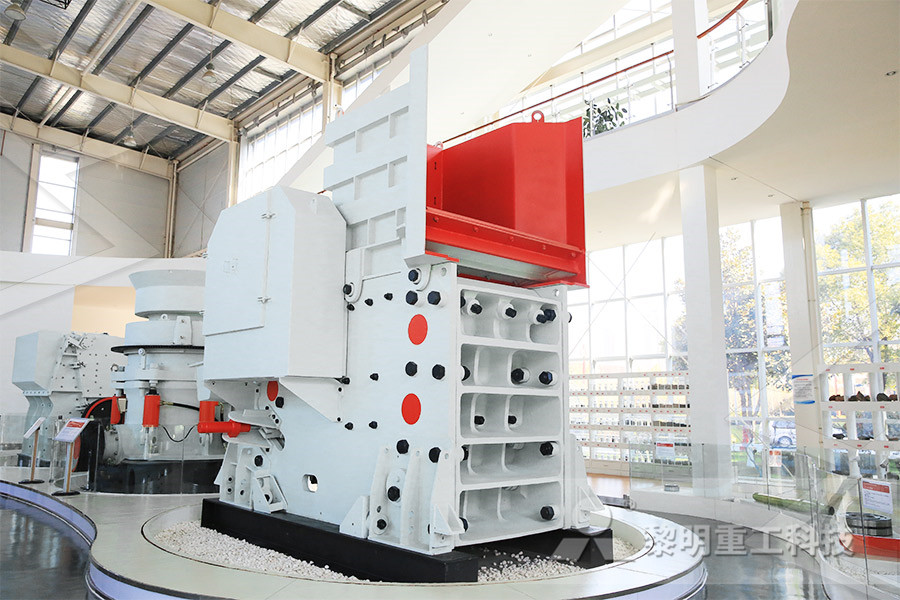

single toggle jaw crusher with its parts

2021-07-31T21:07:59+00:00

Single Toggle Jaw Crusher With Unique Benefits

The crusher with single toggle is a precisely calculated cast iron piece used to adjust the size of the discharge opening and to compensate for wear parts of the jaw plate, toggle plate and toggle plate cushionSandvik CJ613 singletoggle jaw crusher is engineered for even the toughest applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost Sandvik CJ613 SingleToggle Jaw Crusher With A Heavy crusher wear head bushing peru gyratory crusher wear thrust bearing liners c100 jaw crusher spindle speed copper crusher specifications engdu crusher pin bush company crusher plates suppliers head ball 1220x304 mantle cone crusher dowel pin standard rock crusher cones for sale China cursher parts manufacturer,jaw crusher partsjaw crusher liners single toggle crusher with its copper parts

single toggle jaw crusher with its parts

Difference Between Single Double Toggle Jaw Crusher Sep 20, 2014 A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it's partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower Difference Between Single Double Toggle Jaw Double toggle crusher is smaller than a single toggle crusher, is widely used at home and abroad for its lesser price, simple structure and reliable operation 3 Double cavity jaw crusher This type is design firstly by experts of Single Toggle vs Double Toggle Jaw Crusher

Jaw Crushers Kimball Equipment

The Finlay J960 is a compact and aggressive track jaw crusher incorporating a proven direct drive single toggle jaw crusher which gives high capacity with large reduction capacities The plant features a heavy duty Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber, even crushing of the loaded material block, and forced unloading of the finished product by moving the lower jawJaw Stone Crusher Single Toggle vs Double Toggle JXSC Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: singletoggle jaw crushers for a high throughput rate and double • toggle jaw crushers for extremely hard materials and abrasive rock Call on our services and you can count on a wealth of experience and constant innovative drive As a leadingIndustrial Solutions Jaw crushers ThyssenKrupp

Jaw Crusher Components Parts

Jaw Crusher Parts Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the Sandvik CJ613 singletoggle jaw crusher is engineered for even the toughest applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost Sandvik CJ613 SingleToggle Jaw Crusher With A Heavy crusher wear head bushing peru gyratory crusher wear thrust bearing liners c100 jaw crusher spindle speed copper crusher specifications engdu crusher pin bush company crusher plates suppliers head ball 1220x304 mantle cone crusher dowel pin standard rock crusher cones for sale China cursher parts manufacturer,jaw crusher partsjaw crusher liners single toggle crusher with its copper parts

single toggle jaw crusher with its parts

Difference Between Single Double Toggle Jaw Crusher Sep 20, 2014 A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it's partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber, even crushing of the loaded material block, and forced unloading of the finished product by moving the lower jawJaw Stone Crusher Single Toggle vs Double Toggle JXSC Jaw crusher parts that contain frame, movable and stationary plate, bearing, eccentric shaft, toggle jaw, flywheel, eccentric shaft, belt pulley, backmoving spring, jaw plate crusher parts Solid and durable property JXSC the Jaw Crusher Primary Crusher in Mining

MC 140 Z Mobile jaw crusher Wirtgen Group

The single toggle jaw crusher with its weight of over 50 tons can process feed sizes of up to 1300 x 1000 mm edge length and depending on the feed material reaches capacities of up to 750 t/h Frequencycontrolled vibrating feeder Singletoggle jaw crushers Doubletoggle jaw crushers In singletoggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached The pitman is supported by a toggle plate at the bottom of the moveable jaw Toggle plate compressed between moveable jaw and main bodyWhat is a Jaw Crusher? – MEKA Crushing Equipment Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still Jaw Crusher With Different Models

Jaw Crushers Kimball Equipment

The Finlay J960 is a compact and aggressive track jaw crusher incorporating a proven direct drive single toggle jaw crusher which gives high capacity with large reduction capacities The plant features a heavy duty The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155480 (140435) (3) 40ft shipping containers MJ55 JW55 Jaw Crushers JW Series A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers the lower throughput statement is a bit misleading because its partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that single toggle jaw crusher with its parts

single toggle jaw crusher with its parts 2

Jaw Crusher Single Toggle Jaw Crusher With Its Parts 2 A single toggle Blake jaw crusher was available for crushing Assume the shape factor of the feed and the product were the same Determine 1 the rate of the toggle movement that would meet the target production 2 if the toggle rate was reduced by 25 indicate the production rate Single Toggle Jaw Crusher With Its Parts 2 Svedala 1208 1Jawmastertm single toggle jaw crusher 2Within we have more than a century of experience of designing and manufacturing jaw crushersWe also have a wealth of knowledge about customers expectations and needsThis background has led to the cur rent range of jawmaster jaw crushersSingle Toggle Jaw Crusher With Its Parts 2A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to single toggle jaw crusher with its parts

single toggle jaw crusher with its parts forwitsnl

Jaw Crusher Diagram With Its Parts single toggle jaw crusher with its parts 2 URL: flow diagram showing how iron is extracted; different mills in pakistan; penang state Difference Between Single Double Toggle Jaw Crusher Sep 20, 2014 A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it's partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade single toggle jaw crusher with its partsJaw crusher spare partsuyers can place bulk or retail orders with us all year round and expect on time delivery of consignmentshe offered assortment of products is sternly checked, examined by the quality experts to maintain the set industrial standardsur premium grade jaw crusher parts Single Single Toggle Jaw Crusher Manufacturers AtSingle Toggle Jaw Crusher With Its Parts factjeugdnoordnl

single toggle jaw crusher with its parts

Double toggle crusher is smaller than a single toggle crusher is widely used at home and abroad for its lesser price simple structure and reliable operation 3 Double cavity jaw crusher This type is design firstly by experts of Germany it also has two types as single toggle double cavity jaw crusher and double toggle double cavity jaw crusher Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: singletoggle jaw crushers for a high throughput rate and double • toggle jaw crushers for extremely hard materials and abrasive rock Call on our services and you can count on a wealth of experience and constant innovative drive As a leadingIndustrial Solutions Jaw crushers ThyssenKrupp Jaw crusher parts that contain frame, movable and stationary plate, bearing, eccentric shaft, toggle jaw, flywheel, eccentric shaft, belt pulley, backmoving spring, jaw plate crusher parts Solid and durable property JXSC the Jaw Crusher Primary Crusher in Mining

- equipo de cuarto de bano

- flour milling urse in pakistan

- crusher materials mobile

- maquina para procezar chancado

- mill for fine grinding of minerals

- jual tom crusher pertambangan jakarta utara

- different different sizes ampamp prices of wet grinders

- selection and sizing of eand cavating equipment

- List Of Alluvial Mining Equipment

- Equipo de trituración trituración de rocas

- how to separate plastic abs pc after crushing equipment

- vibrating screen manufacturers in south africa

- Molinos De Bauxita En Colombia

- about mobile crushing plant for sale

- lm vertical millverticla roller mills price

- duss grinding mill buyers

- List Of Marble And Quartzite Mohs Scale Hardness

- grinding mill type foss tecator china19430

- Used Gold Wash Plants South Africa r

- used ball mill sale mexi r

- lightroom 4 presets system by slr lounge skachat

- mpare between single toggle anddoubletoddle jaw crusher

- prices for stone crushing equipment south africa

- advantages roll crushers

- plants vs zombies mobile s60v5 r

- 600 ton hour crushing and screening plants

- slag washing equipment for sale r

- crusher plant for limestone 600tph malaysian

- silica sand washing machine sale price zimbabwe

- iowa cedar rapids mfg trituradora de piedra