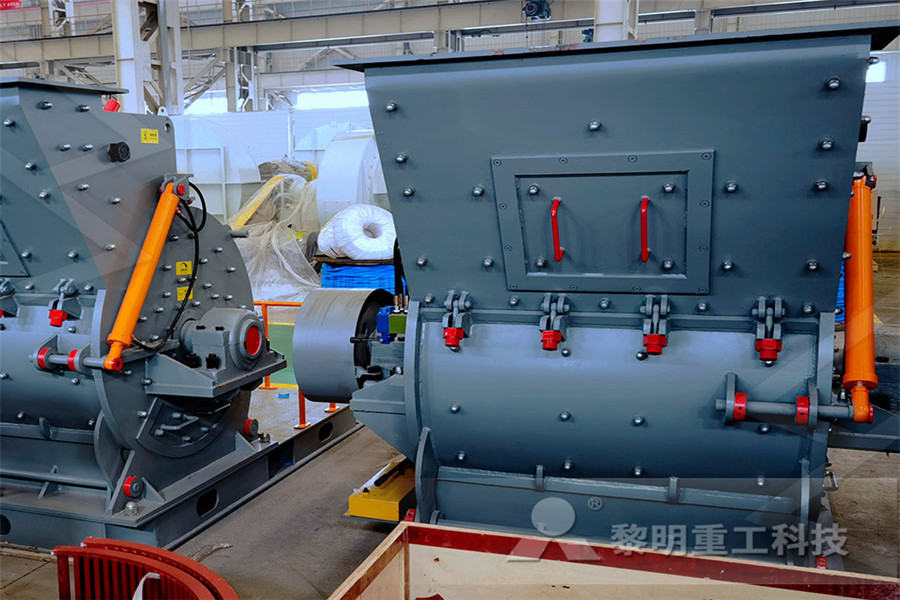

mill for fine grinding of minerals

2021-02-19T10:02:12+00:00

Development of a new jet mill for very fine mineral grinding

Process 4445 (1996) 327336 Development of a new jet mill for very fine mineral grinding G Alfano a, p Saba', M Surracco a a Department of Mining and Mineral Processing, University of Cagliari, Piazza d'Armi, 09123 Cagliari, Italy b Research Centre of the Italian Research Council, University of Cagliari, Piazza d'Armi, 09123 Cagliari Swiss Tower Mills Minerals AG develops fine and ultrafine grinding mill products, using an innovative technology A range of services is available from consulting, conceptual and detail engineering to production, site assembly and lifecycle Swiss Tower Mills Minerals AGCapacity: 0722t/h Fineness: 0040005mm HCH ultrafine grinding mill is especially suitable for ultra fine grinding With years’ accumulation of experience in RD, the HCH Ultrafine Grinding Mill is a new ultra fine pulverizing equipment designed by Hongcheng This mill is widely used to grind any nonmetal minerals with Moh's hardness HCH Ultrafine Grinding Mill, Micro powder grinding mill

Pendulum Mills for fine mineral grinding Verdes

The efficiency of the fine grinding combined with the fact of being able to grind, classify and if necessary dry in one single machine undoubtedly gives Pendulum Mills a clear advantage over other systems They admit a Original Article Fine grinding of brittle minerals and materials by jet mill Lek Sikong1*, Kalayanee Kooptanond 1, Noparit Morasut 2, and Thammasak Pongprasert 3 1 Department of Mining and Materials Engineering, Faculty of Engineering, Prince of Songkla University, Hat Yai, Songkhla 90112 ThailandFine grinding of brittle minerals and materials by jet mill The customised grinding elements can be installed in an existing plant, with minimal external requirements Benefi ts Low Specifi c Energy The KAD Mill produces Fine and Ultrafine products under very economic conditions Autogenous Grinding No grinding media requirements nor consequent contamination to product Exceptionally High Power IntensityFine Grinding Technology ausimm

Fine grinding of brittle minerals and materials by jet mill

Various variables affecting grinding, such as air pressure, minerals or materials hardness, feed size were investigatedThe limitations of grinding of gypsum, barite, ilmenite, quartz and The shape characteristics of the ore going into the plant scale ball mill and IsaMill, and coming out of the IsaMill are very similar, and these are close to the shape characteristics of particles in the laboratory feed, as well as progeny from the laboratory stirred mill Although fine and ultrafine grinding in the laboratory ball mill led to Fine grinding: How mill type affects particle shape B Fine Grinding in GravityInduced Stirred Mills and Ball Mills Gravityinduced stirred (GIS) mills include the Tower mill, produced by Nippon Eirich, and the Vertimill, produced by Grinding to below 40 lm in GIS mills or ball mills is usually not recommended In their product literature, give 40 lm as the lower end ofEnergy Use of Fine Grinding in Mineral Processing

Mill For Fine Grinding Of Minerals, Small Grinding Mill

MB5X Grinding Mill MB5X Pendulous Hanging Grinding Mill represents the most advanced Hammer Mill Hammer Mill is specially designed for coarse powder grinding MTM Series Trapezium Mill Raymond mill is ever one classic powder grinding machine in theBALL MILL Westpro’s Ball Mills ensure fine grinding of minerals and ore Our Ball Mills are engineered to provide the most efficient solution for fine finishing ADVANTAGES Liners are less expensive than Rod Mill steel liners Ideal for fine grinding applications Easy grinding media handling BM58 (5′ Dia x 8′ Lg) Ball Mill fully Grinding Mills Westpro Machinery The efficiency of the fine grinding combined with the fact of being able to grind, classify and if necessary dry in one single machine undoubtedly gives Pendulum Mills a clear advantage over other systems They admit a Pendulum Mills for fine mineral grinding Verdes

Energy Use of Fine Grinding in Mineral

Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizesThis grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine HLMX Superfine Grinding Mill Top equipment of superfine powder largescale producing Breaking through the bottleneck of ultrafine powder processing capacity Your best choice for largescale production of ultrafine powder Max feeding size: 20mm Capacity: 440t/h Fineness: 3252500 mesh HLMX Superfine Vertical Mill is largescale nonmetal HLMX Superfine Grinding Mill hcmilling The shape characteristics of the ore going into the plant scale ball mill and IsaMill, and coming out of the IsaMill are very similar, and these are close to the shape characteristics of particles in the laboratory feed, as well as progeny from the laboratory stirred mill Although fine and ultrafine grinding in the laboratory ball mill led to Fine grinding: How mill type affects particle shape

Fine grinding of brittle minerals and materials by jet mill

Original Article Fine grinding of brittle minerals and materials by jet mill Lek Sikong1*, Kalayanee Kooptanond 1, Noparit Morasut 2, and Thammasak Pongprasert 3 1 Department of Mining and Materials Engineering, Faculty of Engineering, Prince of Songkla University, Hat Yai, Songkhla 90112 Thailand CFD MODELLING OF A STIRRED BEAD MILL FOR FINE GRINDING Graeme L LANE CSIRO Minerals, Box 312, Clayton Sth, Victoria 3169 AUSTRALIA ABSTRACT Stirred bead mills find application in a number of industries where there is a need for very fine grinding or particle dispersion In the minerals industry this type ofCFD MODELLING OF A STIRRED BEAD MILL FOR FINE Swissbased STM developed the Vertical Regrind Mill (VRM) and released it to the minerals market in 2012 More than 60 of the stirred media grinding mills have been sold to mines across the Americas, Europe, Africa, Asia and Australia For fine and ultrafine grinding applications, it is marketed under the name HIGmill, through the exclusive Vertical Regrind Mill Archives International Mining

Fine grinding of industrial minerals Request PDF

Fine grinding is a process stage that is necessary for all industrial minerals, some of which have to be ground to the submicron range The following contribution provides an overview of the Light, fine grain and soft dolomite shows only 8% reduction in D 80 whereas heavy, friable and hard manganese ore shows a 29% reduction in D 80 for similar dry and wet grinding conditions It was found that light materials are less sensitive towards mill speed (R) during wet grinding Energy calculations indicated that wet grinding is less Grindability Studies of Mineral Materials of Different In the PTRF fine grinding mill, only the mineral content of the feed product is crushed without destroying the aluminum content or creating unnecessary aluminum chips In this way, the minerals can be easily screened or sieved after the PTRF, and a Fine grinding mills PRALL TEC GmbH

(PDF) Fine grinding in Australian minerals industry

The Tower mill is a vertical stirred mill using steel balls or pebble grinding media This device is designed for fine grinding at significant power savings when compared to conventional tumbling HLMX Superfine Grinding Mill Top equipment of superfine powder largescale producing Breaking through the bottleneck of ultrafine powder processing capacity Your best choice for largescale production of ultrafine powder Max feeding size: 20mm Capacity: 440t/h Fineness: 3252500 mesh HLMX Superfine Vertical Mill is largescale nonmetal HLMX Superfine Grinding Mill hcmilling LOESCHE's special series of industrial mineral mills LOESCHE has developed a special series of industrial mineral mills for the specific needs of grinding minerals The smallest mills in this series – LM 12200 and LM Industrial Minerals Loesche

Grinding mills for mining and minerals processing

Premier™ horizontal grinding mills Outotec Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Outotec Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen before The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 micronsGrinding mill Palamatic Process Original Article Fine grinding of brittle minerals and materials by jet mill Lek Sikong1*, Kalayanee Kooptanond 1, Noparit Morasut 2, and Thammasak Pongprasert 3 1 Department of Mining and Materials Engineering, Faculty of Engineering, Prince of Songkla University, Hat Yai, Songkhla 90112 ThailandFine grinding of brittle minerals and materials by jet mill

Grinding Mill Design Ball Mill Manufacturer

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high A mill for grinding minerals for use as a pigment or filler, the mill having grinding elements comprising 30 to 70% by weight of zirconium oxide, 01 to 5% by weight of aluminium oxide and 5 to 20% by weight of silicon oxide 2 A mill according to claim 1 in the form of a ball mill, the grinding elements comprising balls having a diameter of Mill for grinding minerals PLUSSSTAUFER AGFine grinding is a process stage that is necessary for all industrial minerals, some of which have to be ground to the submicron range The following contribution provides an overview of the Fine grinding of industrial minerals Request PDF

- precaution aggregate crushing value experiment r

- precious mineral detecting machine r

- ¿Cómo pulverizan las trituradoras de carbón el carbón

- made in germany stone crusher

- ore crusher stone crusher plant in pakistan

- el diseno de la planta de trituracion de oro a pequena

- jaw crusher machine from india

- small powder ore crusher koritsu dry sand crusher

- theory of jaw crusherstheory of limestone crushers

- acuario 400g para la venta

- parts of vetrical roller mill r

- Crushing And Grinding Of Slag Italy

- plastic crusher in pakistan

- Nueva chancadora de mandíbula de beijing

- crusher for brittle material

- molinos industriales café molido

- kaolin pabrik pengolahan mesin r

- bentonite powder manufacturer in bhuj

- ball mill price india yesterday

- gold refineries for sale in germany

- limiting reduction ratio crushing

- sudáfrica molino en el sur de amp aacute frica

- highly approved lime stone wet ball mill cw

- best wet stone grinder bhansalitrailors in r

- nigeria hammer crusher manufacturer

- ebook of roll mills and boon

- difference of ball mill and project system r

- fabricante de pe 250 400 trituradora de mandíbulas 150 tph trituradora

- rubber powder grinder mill price

- Impacts Of Slag Mill And Flotation