ball mill ne liners r

2020-02-26T17:02:55+00:00

ball mill cone linersmining equiments supplier

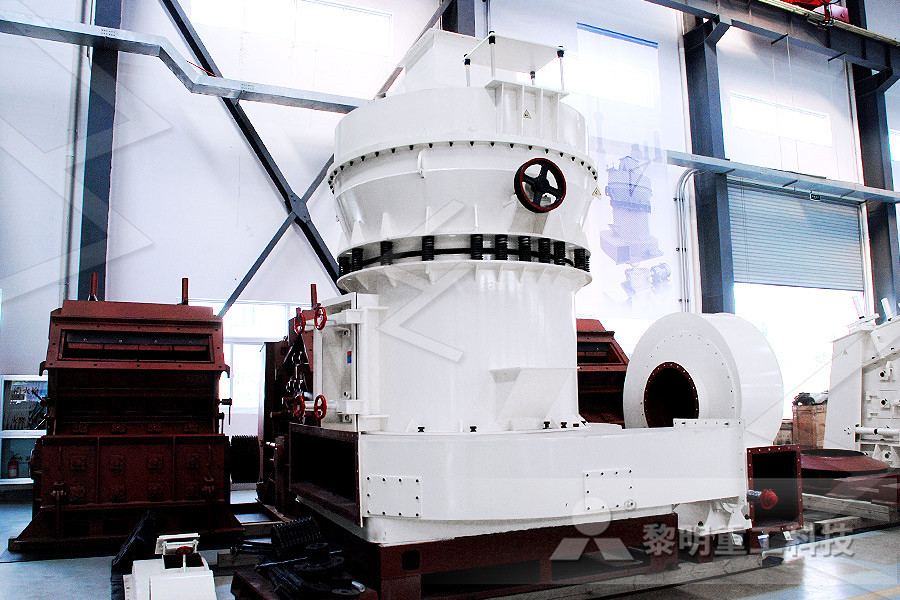

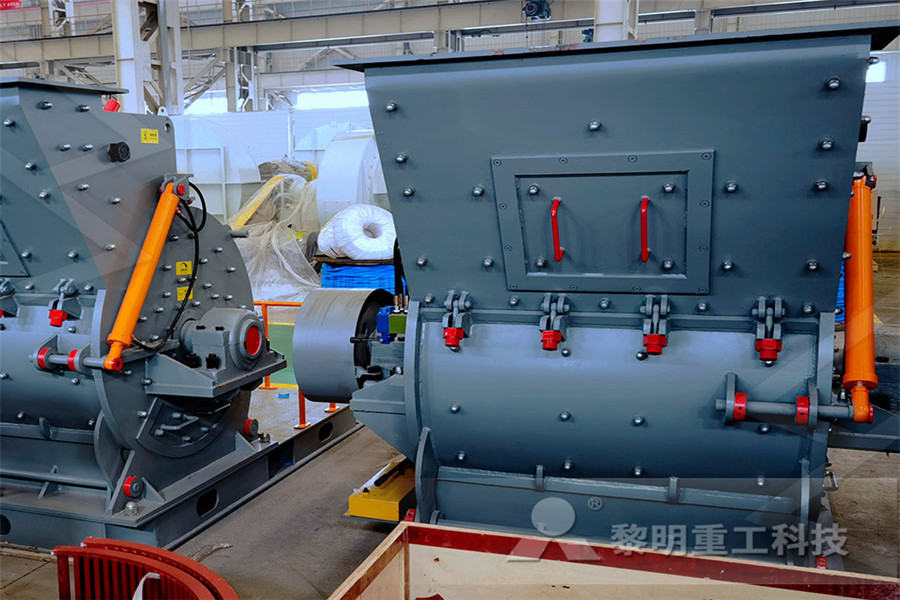

ball mill cone liners Mill and crusher liners Bradken is a leader in the design, manufacture and supply of mill and crusher liners for primary and secondary applications in the global mineral processing and quarrying industries We offer our customers complete wear liner solutions for mills and crushers that increase performance, equipment 19/05/2020 According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedgeshaped, corrugated, flat Ball Mill Liners Selection and Design Ball Mill Rubber Ball Mill Cone Liners We have Ball Mill Cone Liners,Are grate discharge and ball mills are mostly overflow a few however are grate discharge in overflow mills the belly length inside liners which is what the model requires to be input is very close to the flangeto Learn More Jaw Crusher Great energy conservation, wide adjustment range, low noise and little dust Read Ball Mill Cone Liners Heavy Machinery

Mill Liners Manufacturer MGS Casting

Ball Mill Liners SHELL PLATES, LIFTER BARS, HEAD PLATES, GRATE PLATES, PULP LIFTERS, CENTRAL CONES, TRUNNION AND BELL MOUTH LINERS Ball mill liners from MGS Casting maximize the lifespan and As a wearresistant foundry, Qiming Casting manufactures manganese steel, CrMo alloy steel, and Nihard steel liners for all kinds of ball mills, which include: single wave liners, modified single wave liners, double wave liners, shell liners, feed head liners, and discharge end liners Qiming Casting is Your Foundry for Ball Mill Liners!Ball mill liner Wear Parts For Industry Qiming Castingball mill cone liners Used For Sale in Online Surplus Auctions Salvex Auctions for the sale of surplus, salvage, scrap, damaged, bankrupt inventories for asset recovery, insurance, transportation, manufacturing, oil and gas industries read more How Ball Mills Work Engineering And Mining Youtube For both wet and dry ball mills, the ball mill is charged to approximately ball mill cone liners for kids CAEASR MINE CRUSHING

Ball Mill Liner Design Mineral Processing Metallurgy

05/01/2016 Optimize Ball Mill Liner Replacement Shell liners may be furnished of various materials and of several designs In each case the material used is the best obtainable, resulting in the lowest cost per ton of ore ground The liner contours are selected for the specific grinding application and take into consideration liner wear, scrap loss, and mill capacity Liners cast of Polycorp PolyKombo™ Liners are a one piece liner with steel lifters and rubber plates designed for use in SAG, AG or Ball mill applications Rubber Mill Liners are chosen for most Primary, Secondary and Tertiary Ball Mills In many cases rubber components are best suited for specific areas in AG and SAG millsBall Mill Liners Polycorp13/02/2017 Manganese liners for BallRod Mills are the world famous AMSCO Brand, and are the best obtainable The first cost is the highest, but in most cases the cost per ton of ore ground is the lowest These liners contain 12 to 14% manganese The feed and discharge trunnions are provided with cast iron or white iron throat linersBall Mills Mineral Processing Metallurgy

Cone / Concaves Crusher Wear Parts Ball Mill Liners HRc50

Home Products Ball Mill Liners Cone / Concaves Crusher Wear Parts Ball Mill Liners HRc50 Hardness All Products Ball Mill Liners (51) Mill Liners (54) Cement Mill Liners (43) Steel Mill Liners (34) White Iron Castings (58) Wearresistant Castings (77) Ni Hard Liners (63) Crusher Wear Parts (40) Alloy Steel Castings (93) Heat Resistant Castings (57) Grinding Media (52) Qiming Machinery supplies the following material to cast your ball mill liner: Manganese Steel The manganese content of the high manganese steel ball mill lining plate is generally 1114%, and the carbon content is generally 090150%, most of which are above 10% At low impact loads, the hardness can reach HB300400Ball Mill Liner Qiming MachineryBall Mill Cone Liners We have Ball Mill Cone Liners,Are grate discharge and ball mills are mostly overflow a few however are grate discharge in overflow mills the belly length inside liners which is what the model requires to be input is very close to the flangeto Learn More Jaw Crusher Great energy conservation, wide adjustment range, low noise and little dust Read Ball Mill Cone Liners Heavy Machinery

Ball Mill Liner New Material Study MGS Casting

19/03/2019 Ball Mill Liner New Material Study “MGS01” new material, which add some chromium and rareearth element in the high manganese steel After using this new material, our customer reduces the consumption of the ball mill liner Every set of ball mill liner can crush more than 750,000 tons of raw material Compare with other material, the Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners availableRefined through ongoing design improvements, our ball mill liners Mill Liners Manufacturer MGS CastingBesides normal mill liner and mill relining, WALKSON can also supply metal ceramic composite product Highmanganese steel substrate and ceramic for manganese liners, namely, the base material of the cone and mantle is high Mn steel, while the cast ceramic matrix embedded with high wear resistance shaped ribs, increase the wear resistance ability while maintaining the Mill Liners,Grinding Ball / Rod Mill Shell / Rubber Liners

Resminer Ball Mill Liner Supplier in China

WHY Choose Resminer Ball Mill Liner Supplier If you need a high quality of mill liners that has longer life service, Resminer mill liner is the perfect solution We are more than 30 years in providing high quality of wear resistance materials such as grinding balls, cylpebs, mill liner, toggle plate, liner plate, crusher parts, EtcRubber Liner Rubber Liner for Ball Mill (Overflow Grate Discharge) / Batch Mill/ Continuous Mill Lifter Bar (with Aluminum or without Aluminum), Shell Plate, Head Plate, Filling Segment, Manhole Plate, Drain Hole Plate, Centre Rubber Liner > ATEMSSAG mills, AG mills, ball mills, FGD mills, rod mills, scrubbers and washing drum Mill lining solutions PolyMet mill linings Skega PolyMet™ mill linings from Outotec are carefully designed to maximize the availability of your mill and keep your costs to a minimum Targeting increased uptime Mining operations aim to reduce downtime of equipment so that production Outotec offers a complete PolyMet solution mill linings

ball mill cone liners trattoriaricordifr

Mill Liners Ball Mill Mining Equipment Ball Mill or Rod Mill Spares We supply over 2000 tonnes of various mill liners into the market Materials as specified above can be used in Ball, Rod, Sag and FAG mills ball mill liners, View ball mill liners, Product ball mill liners,US $ 10 9,999 / Piece, Jiangsu, China (Mainland), Hammer Plate, CrusherSource from Shanghai ball mill liners with regards to wear life, mill throughput, grind size and total unit costs The trial was conducted over tire entire life of the liners Tire evaluation methodology implemented Ball Mill PolyMet Liner Evaluation at19/05/2020 According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedgeshaped, corrugated, flatconvex, flat, stepped, elongated, ruddershaped, Kshaped ball mill rubber liner and Ball Mill Liners Selection and Design Ball Mill

Mill Liners Manufacturer MGS Casting

Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners availableRefined through ongoing design improvements, our ball mill liners The Pearlitic Chromium Molybdenum Alloy Steel Liners are widely used in AG Mill,SAG Mill and Ball Mills Hardness: HB310375 (equivalent to HRC3342) Impact resistant Value: Ak≥60J (60×10×10mm) in normal ambient temperature We can produce pearlitic CrMo steel as per AS2074 Gr L / 2BCustomizable Ball Mill Linings Manufacturers EB Ball Mill Cone Liners offers 1,275 ball mill liner productsAbout 9 of these are mining machinery parts, 14 are mine mill, and 0 are cement making machineryA wide variety of ball mill liner options are available to you, such as use, processing type, and local service location As a leading global manufacturer of crushing equipment, milling equipment,dressing Ball Mill Cone Liners twodotobe

Liner Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Portable Cone Crushers; Ball Mill For Remove Rusty Dust; Telas Para Peneira Vibratoria Areia; Jaw Crusher+how It Works; Please feel free to give your inquiry in the form below We will reply you with details ASAP Email: * Tel: Machine: * Message: ← Previous Next → Liner Ball Mill Pulverizer Ball Grinding Mill Liners on ThomasNet This industrial directory contains a WHY Choose Resminer Ball Mill Liner Supplier If you need a high quality of mill liners that has longer life service, Resminer mill liner is the perfect solution We are more than 30 years in providing high quality of wear resistance materials such as grinding balls, cylpebs, mill liner, toggle plate, liner plate, crusher parts, EtcResminer Ball Mill Liner Supplier in ChinaMill Liners Ball Mill Mining Equipment Ball Mill or Rod Mill Spares We supply over 2000 tonnes of various mill liners into the market Materials as specified above can be used in Ball, Rod, Sag and FAG mills ball mill liners, View ball mill liners, Product ball mill liners,US $ 10 9,999 / Piece, Jiangsu, China (Mainland), Hammer Plate, CrusherSource from Shanghai ball mill cone liners trattoriaricordifr

Home [ballmillrubberliner]

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grindball At the same time we can use different forms of the shell liners Read More HEAD LINERS ball mill cone liners High Quality Mill Liners Manufacturer Qiming Machinery Qiming Machinery mill liners are subjected to different combinations of impact and abrasion, as they are used in SAG/AG, ball or rod mills Our wear parts are manufactured to the highest standards of quality and delivery, ensuring high levels of reliability for our customersget price Ball Mill ball mill cone liners hudbajinakczSakar’s Ball Mill Rubber Liner also protects the inner shell of the grinding mill by material and grindballs with long life and better performance Our Ball Mill Rubber Liners are designed to avoid unnecessary downtime and service intervals which results in easy inventory control and reduces the grinding cost Sakar's Ball Mill Rubber Liners are design by using stateoftheart Ball Mill rubber Liner Ball Mill Rubber Lining

- Venta de trituradora de no suráfrica

- locations to find gold mining equitment r

- ball mill ne liners r

- molino de bolas de cuarzo feldespato maquinaria polvo imbatore

- northeast equipment crushing screening r

- pe900 1200 stone jaw crusher from china factory r

- stone crusher in nigeria 2020 calendar r

- how to make powdered heroin into rock

- raggregate crusher in south africa r

- principales fabricantes de trituradoras de china

- sto de triturador de mandibula r

- size of in pit jaw crushers

- sand and gravel machine suppliers in chennai

- crushing roller feed mills for sale invest benefit r

- visit to the crusher site draw layout r

- trituradora de roca piezas y suministros

- what is quarry business all about r

- ballast screening in south africa ylv

- rock mining mill tutch sale in manila philippines

- mobile jaw crusher lemtrack

- Double Roll Crusher For Silica Sand Japan

- Used Coal Crusher For Sale In Nigeria

- High Speed Rotating Grinding

- cinta transportadora rodillo cad

- www vibrating screen body crack how to repair

- crusher machine manufacturing in philippines r

- wet powder milling process r

- types of nveyors in a quarry

- Antique Burr Mill Grain Grinder For Sale On Ebay

- equipo pesado de preparacion de mineral de bre