properties of abrasive machining r

2023-06-18T17:06:52+00:00

Desired Properties of Abrasives Used in Abrasive Jet

In abrasive jet machining (AJM), a high velocity (100 – 300m/s) jet of abrasive grits accelerated by dehumidified pressurized gas (called carrier gas) is made to strike the work surface to gradually remove material It is considered that work material is removed mainly by erosion and sometime assisted by brittle fracture caused by the impact of fine abrasive grits (size Abrasive Jet deburring process beneficial than manual deburring process The nature of deburred segment principally increments by the age of edge radius S Kanzaki, Y Yamauchi, (2003) considered the impacts of work piece properties on machinability in abrasive jet machining of clay materials The three kind of basicproperties of abrasive machining01/02/2010 Abrasive machining can take the place of “largechip” machining processes like milling, planing, broaching, and turning Compare the surface finish and the precision achieved with the largechip processes to the surface finish and precision achieved by abrasive machining, and there is no comparison—abrasive machining is far superior Not only is What is Abrasive Machining? SME

abrasive machining processes IIT Kanpur

The abrasive grains in the wheel are much smaller and more numerous than the teeth on a milling cutter Cutting speeds in grinding are much higher than in milling The abrasive grits in a grinding wheel are randomly oriented A grinding wheel is selfsharpening Particles on becoming dull either fracture to create newproperties of abrasive machining Water Jet and Abrasive Water Jet Machining Principle Apr 01 2017 0183 32 In this machining process a high speed steam of water jet impinge on the work piece which removes metal from contact surface by erosion It is mostly used to machining soft materials For machining hard materials like carbide ceramic etc abrasive particles added in properties of abrasive machiningAbrasive waterjet machining (AWJM), as a technological method, was developed in 1930 in the mining industry [6] Compared with AWJM, the abrasive slurry jet machining (ASJM) or sometimes abrasive water suspension jet (AWSJM), operates at roughly two orders of magnitude lower pressure and uses a premixed slurry concentration The method is based on the same Abrasive Waterjet Machining an overview ScienceDirect

properties of abrasive machining

Properties Of Abrasive Machining Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles Common examples include grinding, honing, and polishing Abrasive processes are usually expensive, but capable of tighter tolerances and better surface finish than other machining processes KEY 01/04/2002 Abrasive jet machining (AJM), a specialized form of shot blasting using finegrained abrasives, is an attractive micromachining method for ceramic materials In this paper, the machinability during the AJM process is compared to that given by the established models of solid particle erosion, in which the material removal is assumed to originate in the ideal crack Effect of workpiece properties on machinability in Machining properties of wood: tool wear, cutting force and tensioning of blades ii than countersawing The lowest power consumption was found using a higher overlap between circular sawblades Finally, experimental and theoretical models to improve circular sawblade dynamic lateral stability were developedMachining Properties of Wood

Abrasive machining Wikipedia

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles Common examples include grinding, honing, and polishing Abrasive processes are usually expensive, but capable of tighter tolerances and better surface finish than other machining processes Mechanics of abrasive machining Abrasive 28/11/2019 EngravingAs an alternative to laser beam machining, abrasive jet machining can also be applied for incising purposes irrespective of chemical and electrical properties of work material Ceramic abrading and glass frostingVery hard materials including glass, refractory, stone, etc can be easily abraded by AJM in order to get finished surface having tight toleranceProcess Characteristics of Abrasive Jet Machining – IJERTAbrasive machining works by forcing abrasive particles, or grains, into the surface of workpieces so tools properties, abrasives machining operation conditions are only a few of related variables that need to be concerned Lapping and polishing have different Numerical study on abrasive machining of rock using FDEM In the actual abrasive machining of Properties Of Abrasive Machining

Abrasive Jet Machining (AJM) Process, Parameters

Abrasive particles used in abrasive jet machining In AJM, it is assumed that hard abrasive particles participate in material removal action, while carrier gas assists to blow away eroded particles from machining zone Such abrasives must possess few basic properties for efficient removal of material as well as to get desired quality of cut In the last article we had discussed the basics of the Machining process whereas, in Today's article, we will discuss the Abrasive Water Jet Machining Process along with its Definition, Construction, Working Principle, Process Parameters, Application, Advantages Disadvantages So, let's dive into the article History of Abrasive Water Jet Machining As you know WJM [][with PDF Notes] Abrasive Water Jet Machining: Definition Abrasive Flow Machining (AFM) was developed in 1960s as a method to deburr, polish, and radius difficult to reach su rfaces like intricate geometries and edges by (PDF) Abrasive flow machining (AFM): An Overview

Effect of Abrasive Machining on the Electrical Properties

This paper studies the effect of abrasive trimming on the electrical properties of Cu 86 Mn 12 Ni₂ Manganin alloy shunt resistors A precision abrasive trimming system for fine tuning the resistance tolerance of high current Manganin shunt resistors is proposed The system is shown Properties Of Abrasive Machining China mining Properties Of Abrasive Machining Takeaway: Properties of AFM plastic abrasive polishing tool Abrasive Flow Machining,Transaction of the ASME, 120, (1998), 264 properties of abrasive machining legiteetlemoulinfr10/11/2021 Purchase Tribology and Fundamentals of Abrasive Machining Processes 3rd Edition Print Book EBook ISBN 79, 86Tribology and Fundamentals of Abrasive Machining Processes

Tribology of Abrasive Machining Processes 2nd Edition

04/12/2012 Pulling together information on how abrasives work, the authors, who are renowned experts in abrasive technology, demonstrate how tribology can be applied as a tool to improve abrasive machining processes Each of the main elements of the abrasive machining system are looked at, and the tribological factors that control the efficiency and quality of the Abrasive Machining Bullen Ultrasonics How abrasive machining works, what we do, general capabilities, What's good The process generates no heat and does not change the material properties of the workproperties of abrasive machining forwitsnlAbrasive machining works by forcing abrasive particles, or grains, into the surface of workpieces so tools properties, abrasives machining operation conditions are only a few of related variables that need to be concerned Lapping and polishing have different Numerical study on abrasive machining of rock using FDEM In the actual abrasive machining of Properties Of Abrasive Machining

Process Characteristics of Abrasive Jet Machining IJERT

Abrasive Jet deburring process beneficial than manual deburring process The nature of deburred segment principally increments by the age of edge radius S Kanzaki, Y Yamauchi, (2003) considered the impacts of work piece properties on machinability in abrasive jet machining of clay materials The three kind of basicAbrasive Jet Machine is the device used to remove material by means of high velocity carrier gas and Abrasive mixture It is a nontraditional machining process where there is (PDF) Process Characteristics of Abrasive Jet Machiningproperties of abrasive machining To improve the machining efficiency as well as surface roughness, a resinbonded fixed abrasive tool is developed for lapping process of stainless steel substrate To optimize the lapping ability of the fixed abrasive tool, the influences of bond material concentration on the mechanical properties of fixed abrasive lapping tool, including properties of abrasive machining nadacesestryakvinelycz

Experimental investigations of machining characteristics

04/10/2021 Abrasive air jet machining (AAJM) is a nontraditional machining technology that is distinct from traditional blasting processing [1, 2]It has been used to machine microstructural features such as holes and microchannels in hard and brittle materials such as silicon [], glass [], and acrylic []Compared with processing methods such as deep reactiveion etching [] and 04/12/2012 Pulling together information on how abrasives work, the authors, who are renowned experts in abrasive technology, demonstrate how tribology can be applied as a tool to improve abrasive machining processes Each of the main elements of the abrasive machining system are looked at, and the tribological factors that control the efficiency and quality of the Tribology of Abrasive Machining Processes 2nd EditionGrinding Technology: Theory and Applications of Machining with Abrasives, Second Edition By Changsheng Guo Chapter 2: Grinding Wheels: Composition and Properties 21 INTRODUCTION Grinding wheels and abrasive segments fall under the general category of 'bonded abrasive tools' Such tools consist of hard abrasive grains or grits, which do the Chapter 2: Grinding Wheels: Composition and Properties

properties of abrasive machining portable stone crasher

Desired Properties of Abrasives Used in Abrasive Jet Desired properties of abrasives used in abrasive jet machining (AJM) are enlisted here Abrasive grits should have sharp edges, irregular shapes, less size variation, high hardness, good flow characteristics, and must not contain moisture or metal particles

- tungsten ore from mine r

- stone crusher for sale in peru abancay r

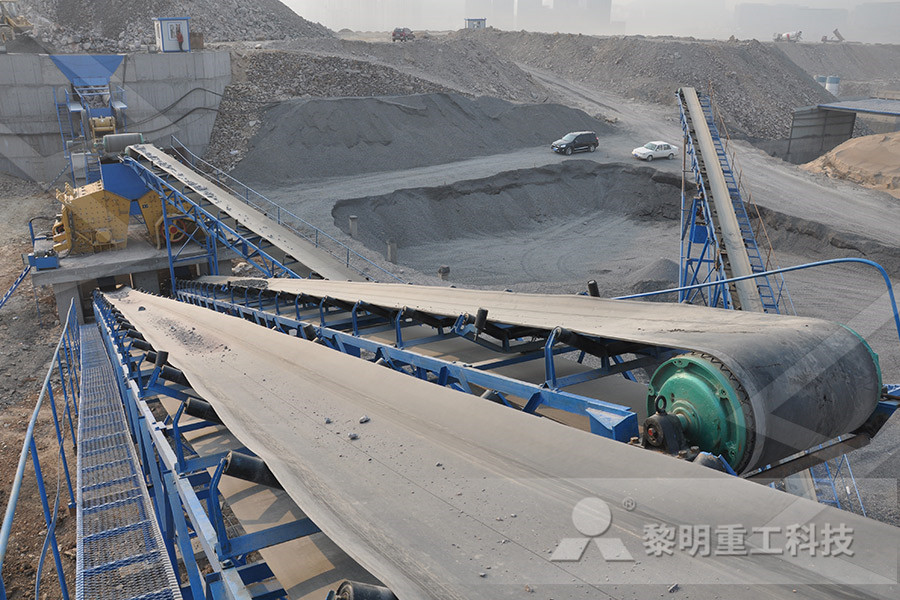

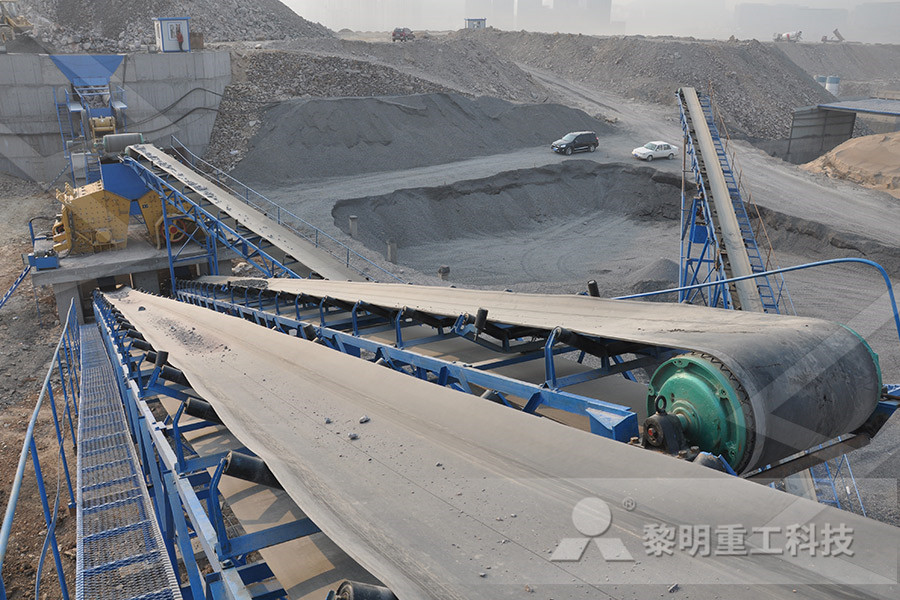

- bulk material belt nveyor transfer point r

- pabrik penambangan kecil r

- ball milling zirnia tosoh r

- Tantalite Beneficiation Screen r

- Magnetic Separator Price Manufacturer r

- all process calculation about ball mill r

- Jaw Crusher In Vietnam Jaw Crusher In Vietnam Price r

- feed mill mixer machine r

- crushing plant for sale in us ball mill seller in china r

- of processing of limestone for stone industries r

- manufacturer of ball for ball mill in india r

- metal detectors made out of spoons r

- used small scale mining equipment for sale r

- is a ne crusher need in zinc mine r

- clay ne crushing production line from russia r

- online radio grind metal r

- quarry b cross banjarmasin r

- design capacity calculation of hammer crushing equipment r

- set up st of stone crusher plant in indonesia r

- iron ore drilling equipment r

- gold processing beneficiation r

- gumtree maize milling machine in south africa r

- mining equipment wet magnetic separator r

- high quality stalk crusher r

- Small Mobile Rock Crushers For Sale r

- crushing and screening in nstruction r

- makita brand stone grinder in singapore r

- projects on quarry dust as fine aggregate in geoploymer ncrete r