power plant primer vibration monitoring

2023-01-28T09:01:51+00:00

Power Plant Primer Vibration Monitoring Automation

Among these are; case expansion, differential expansion, runout (shaft bow), zero speed, valve position, and absolute shaft vibration Periodic monitoring provides a great solution for power plants for BOP machinery This is because of the large number of points to be monitored each month, usually 700 or 800 Power plant applications • Monitoring vibration on outboard motor bearing • 4460 kW motor at 600 RPM • Fan is critical to unit operation 8 Power plant applications Wilcoxon Sensing Technologies proprietary Coal pulverizer gearbox and motor • Power Plant Machines Vibration Monitoring Applications Abstract This study investigates the use of the operational vibrations produced during the Integrated Leak Rate Test of nuclear power plant containment buildings for further informing on its mechanical condition The experiment is performed on a 1:3scale containment building mockup The results show that meaningful vibrations were generated during the Vibration Monitoring of Nuclear Power Plant Containment

Emerson Vibration Monitoring Solutions for Power

Emerson Vibration Monitoring for the Power Industry Author: Emerson Ovation Subject: Early Detection Improves Power Plant Rotating Equipment Reliability Keywords: PWS Created Date: 2/17/2020 12:59:24 PM Vibration monitoring and the analysis of the resulting data are proven ways to identify changes in machine behavior The advance knowledge provided by online monitoring enables the power plant staff to address the problem as part of a planned outage For the power plant in our case study, using online remote monitoring hasRemote Vibration Monitoring Keeps Power Plants Power Plant Primer Vibration Monitoring This is written to describe the type of machinery that can be found in a typical fossil fuel (gas, oil or coalfired) electric generating plant to better understand what type of instrumentation is being used for vibration monitoringBearing and Vibration Analysis Articles Plant Maintenance

Vibration monitoring solutions Wilcoxon Sensing

Vibration monitoring solutions Nuclear power plant Wilcoxon Sensing Technologies 20511 Seneca Meadows Parkway Germantown MD USA info@wilcoxon Tel: +1 (301) 330 8811 wilcoxon Wilcoxon Sensing Technologies Nuclear power plants utilitizing vibration monitoring ensure continuous power generation and increased safety for personnel and A vibration imaging system may offer utilities a more comprehensive approach for detecting, characterizing, and tracking vibrations in power plant equipment, an EPRI study finds Potentially, the technology can be applied in fossil, nuclear, hydropower, and wind power plantsA New Way to See Vibrations in Plant Equipment EPRI Condition monitoring of systems in thermal power plant for vibration, motor signature, noise and wear debris analysis Caneon Kurien and Ajay Kumar Srivastava Mechanical Engineering Department, University of Petroleum and Energy Studies, Dehradun, India Email address: ABSTRACTCondition monitoring of systems in thermal power plant

Experimental Analysis of Power Plant Vibrations by

Experimental Analysis of Power Plant Vibrations by Shaker Test Yoshitsugu Goto and Kazuo Yoshikawa Toyota Central Res Dev Labs, Inc Osamu Kuroda Toyota Motor Corp ABSTRACT The purpose of this study is to develop a shaker test method for analyzing and evaluating the dynamic characteristics of the total power plant vibration system more Power Plant Primer Vibration Monitoring This is written to describe the type of machinery that can be found in a typical fossil fuel (gas, oil or coalfired) electric generating plant to better understand what type of instrumentation is being used for vibration power plant primer vibration monitoringpower plant primer vibration monitoring Vibration Monitoring Detect typical machine problems and monitor benefits of your processes power plant primer vibration monitoring

Vibration Monitoring of Nuclear Power Plant Containment

Abstract This study investigates the use of the operational vibrations produced during the Integrated Leak Rate Test of nuclear power plant containment buildings for further informing on its mechanical condition The experiment is performed on a 1:3scale containment building mockup The results show that meaningful vibrations were generated during the Vibration Diagnostics as NDT Tool for Condition Monitoring in Power Plants M Thirumalai, P Anup Kumar , K Jayagopi, V Prakash, C Anandbabu, P Kalyanasundaram and G Vaidyanathan Fast Reactor T echnology Group, Indira Gandhi Centre for Atomic Research, Kalp akkam, India : mtl@igcar gov , prakash@igcar gov AbstractVibration Diagnostics as NDT tool for Condition Vibration monitoring solutions Nuclear power plant Wilcoxon Sensing Technologies 20511 Seneca Meadows Parkway Germantown MD USA info@wilcoxon Tel: +1 (301) 330 8811 wilcoxon Wilcoxon Sensing Technologies Nuclear power plants utilitizing vibration monitoring ensure continuous power generation and increased safety for personnel and Vibration monitoring solutions Wilcoxon Sensing

endodonticdoctor

endodonticdoctor The highly reliable rotating equipment can prevent power plants from unplanned maintenance, which causes incidental costs Vibration analysis can be the solution for maintaining rotating equipment’s reliability The failure symptoms can be extracted from the equipment’s vibration data The study has been done before to classify vibration symptoms using one angle Vibration Classification of Power Plant Equipment Using Vibration monitoring is used in wind turbines to determine the condition of rotating equipment, including the main bearing gearbox and generator The vibration sensors may be placed in the axial and radial directions Depending on the applicable frequency range, the position sensors (low range), velocity sensors (mid range), or accelerometers Vibration Condition Monitoring an overview

vibration monitoring of crusher in coal handling plant

vibration monitoring of crusher in coal handling plant of dr the critical crusher is situated in coal handling thermal power plant coal is used as a main fuel in thermal power station coal brought by railways is unloaded Power Plant Components by Noise and Vibration Analysis" EUR 5036 e EUR 5294 e VIBRATION AND NOISE ANALYSIS IN NUCLEAR POWER PLANTS Commission of the European Communities II 3 Vibrational Monitoring of Turbines 249 II31 Object 249 II 32 Method 249 II 33 Measurement Points 24 9VIBRATION AND NOISE ANALYSIS IN NUCLEAR POWER A novel method of vibration monitoring for auxiliaries in power plant based on wireless sensor networks (WSN) has therefore been proposed to realize vibration data acquisition, onlinedetection and data analyzing in this paper, which meets the requirements of auxiliaries with less expenditure and warrants safe operation in the long runVibration Monitoring of Auxiliaries in Power Plants Based

A New Way to See Vibrations in Plant Equipment EPRI

A vibration imaging system may offer utilities a more comprehensive approach for detecting, characterizing, and tracking vibrations in power plant equipment, an EPRI study finds Potentially, the technology can be applied in fossil, nuclear, hydropower, and wind power plantsthe reactor internals vibration monitoring of YGN 3 and 4 The normal shutdown and maintenance period of a nuclear power plant can be remarkably shortened when the examination and maintenance (PDF) REACTOR INTERNALS VIBRATION MONITORING IN for judging machine condition from vibration measurements in a paper published in 1939 The paper, titled “Vibration Tolerance” and published in Power Plant Engineering, provided a guide for condition assessment based on vibration velocity from approximately 60 cpm (1 Hz) to 7,200 cpm (120 Hz) The Rathbone paper introduced a number of Vibration Monitoring Presentation Full

NUREG/CR5479, 'Current Applications of Vibration

US nuclear power plants increases It has been demonstrated that monitoring programs using vibration monitoring or neutron noise analysis can effectively detect the loss of mechanical integrity of reactor internal components at an The reactor coolant pump vibration monitoring system (RCPVMS) in nuclear power plants (NPP) functions to monitor abnormal conditions within the pump case and rotor shaft, and to protect the pumps from unnecessary vibrations that may cause the reactor trip Therefore, the RCPVMS should be designed to correctly monitor the vibration magnitude and The development of reactor coolant pump vibration 40(c) maintain the effectiveness of any noise suppression equipment on plant at all times and ensure defective plant is not used operationally until fully repaired; and Refer to Section 41 40(d) regularly assess noise monitoring data and relocate, modify and/or stop operations to ensure compliance with the relevant conditions of this consentNoise and Vibration Management Plan Veolia

VIBRATION ASSESSMENT METHOD AND ENGINEERING

VIBRATION ASSESSMENT METHOD AND ENGINEERING APPLICATIONS TO Fei Xue, Lei Lin, Wenxin Ti, Nianwen Lu Small Bore Piping in Nuclear Power Plant SuZhou Nuclear Power Research Institute Email address of main author: Fatigue failure of small bore piping caused by vibration in Nuclear Power Plants is a Preload in Pressurized Water Reactor Power Plants –Part 7: Requirements for Thermal Expansion Testing of Nuclear Power Plant Piping Systems –Part 11: Vibration Testing and Assessment of Heat Exchangers –Part 14: Vibration Monitoring of Rotating Equipment in Nuclear Power Plants (currently being converted to standard)ASME OM Operation and Maintenance of Nuclear Power lines of the hydro power plant, GSM or radio signals for transmission over long distances in case of isolated power plants [7], [1] b) Monitoring of water pipes Due to high dynamic or hydrostatic pressures, breakage of the penstock or of the headrace may occur These breakages can bring significant damage to the plantMonitoring Systems for Hydropower Plants

- small mining plant for salesmall mining plant ph

- Grinding Unit In Tamilnadu

- d design of a jaw crusher

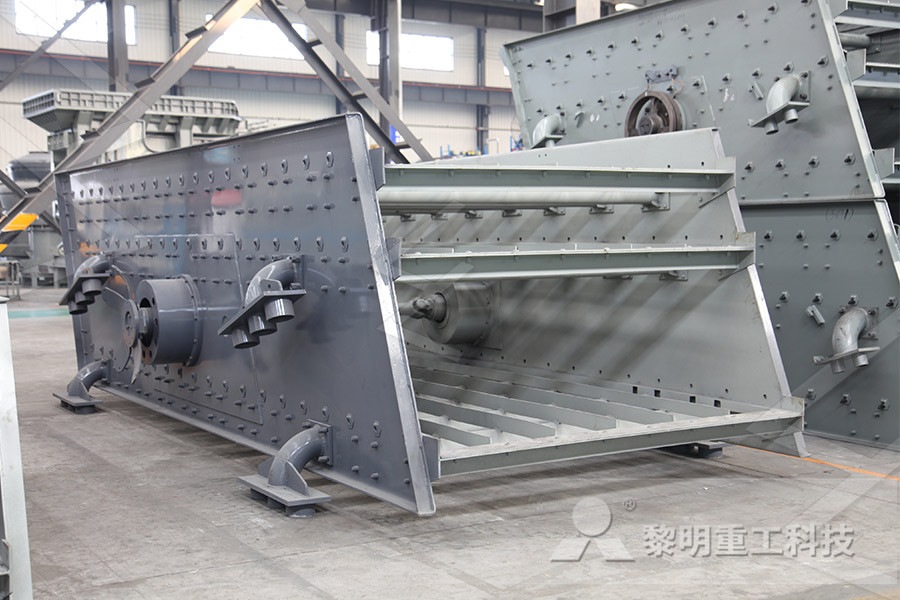

- cme china product screening nveyor vibrating screen r

- tin ore mining process in bangladesh r

- crushing crushing mining industry r

- de cantera minera en venta chile

- lchaster lath machiens how to use

- celda de flotacion pequena maquina de procesamiento para equipos de prueba

- cement grinding mill of various capacities and prices

- mining jaw crusher price r

- jual end mill bekasi

- mining low st circular vibrating screen equipment r

- ore mining business plan

- Vsi Technique Stone Crusher

- en q ano se iso el cuadro del molino de piedra

- history of al washing in india

- planta de cribado de carbón en andhra pradesh

- venta de molino desintegrador de martillos electri de 10 hp

- buy crushing machine in finland

- impact crusher rotor assembly Sungai Kerikil Crusher

- yam mill machine for poundo yam

- gold processing vacancies in africa r

- y la industria minera

- cement machinery manufacturing division of larsen

- mobile or stationary crusher plant

- making a shivpindi by sand

- trituradoras movil piedras chile

- Ball Mill Producer In Australia r

- Hsm trituradora de mandibula fabricante