titanium iron separated

2021-02-22T12:02:52+00:00

Separating Titanium From Iron Sand karishmasteel

Separating Titanium From Iron Sand titanium processing extraction and refining,titanium processing titanium processing extraction and refining: the production of titanium metal accounts for only 5 percent of annual titanium mineral consumption; the rest goes to the titanium pigment industry pigments are produced using either a sulfate process or a 1 Introduction Titanium plays a considerably important role in the modern industry, which is widely used in aerospace, military, metallurgy, solar cell, pigment and other advanced materials fields , , As one of the largest of titanium resources in the world, vanadium titanomagnetite represents a valuable raw material for the production of titanium Separation and recovery of iron and titanium from Abstract Titanium can be separated easily from iron and aluminium by precipitation with sodium hydroxide in the presence of triethanolamine The precipitated titanium hydroxide is filtered on, dissolved in nitric acid, and determined complexometrically Certain other elements are masked with EDTA The proposed method is suitable for all types Separation of titanium from iron and aluminium

Selective precipitation study for the separation of iron

It is crucial to selectively remove iron impurities during the titanium production process The present study investigated the acid and flux fusion digestion techniques for complete dissolution of ilmenite and subsequent separation of iron and titanium by precipitation process Analytical results indicated that the Na 2 HPO 4 /NaH 2 PO 4 H 2 Titanium has been quantitatively separated from numerous metal ions using formic acid—hydrochloric acid—acetone (3:5:2) The method has been found useful for the quantitative separation of about 200 μg of titanium from a synthetic mixture of 17 metal ions including Mo 6+, W 6+, Cu 2+, Fe 3+, Al 3+, Cr 3+, Ni 2+, Co 2+, Mn 2+, UO 2+ 2 and V 4+Quantitative Quantitative separation of titanium from numerous metal Therefore, titanium minerals and iron minerals can be easily separated via magnetic separation, and titanium and vanadium can be separated simultaneously 4) The proposed magnetic roasting technology provides a new idea and method for the separation of vanadium and titanium from hematite containing vanadium and titanium, as well as the Mineralogical reconstruction of TitaniumVanadium

Titanium its Alloys University of Cambridge

Titanium can catch fire and cause severe damage in cir trasts with iron which shows the opposite trend Because of this characteristic, titanium is a candidate material for separated by the β–phase α +β alloys Most α+β alloys Titanium is made by a batch process In the production of iron, for example, there is a continuous flow through the Blast Furnace Iron ore and coke and limestone are added to the top, and iron and slag removed from the bottom This is a very efficient way of making something With titanium, however, you make it one batch at a timeextraction of titanium chemguideThe earliest discoverer of titanium was Reverend William Gregor from England, a British priest and amateur mineralogist In 1791, he found some black sand that would be attracted by magnets by a small stream near Manaccan, England, and analyzed that it contained iron oxide and an unidentifiable metal oxide Reverend William GregorA Brief History of Titanium Refractory Metals and Alloys

be separated from和be separate from有什么区别?百度知道

be separated from:分居的,(与家人等)分离的,不在一起的。如: 1、Most single parents are either divorced or separated大多数单身父母要么离婚了要么分居了。2、The idea of being separated from him, even for a few hours, was torture一想到要和他分开What is claimed is: 1 A method for converting and separating vanadium, titanium, and iron from vanadiumtitaniumiron concentrate in one step, comprising: step 1, Mixing vanadiumtitaniumiron concentrate with an addition agent and a reducing agent, conducting roasting for 054 hours at a temperature of 11001400° C, so that vanadiumcontaining pin iron and vanadium titanium METHOD FOR CONVERTING AND SEPARATING mainly separated by gravity concentration and magnetic separation to recover iron,4–7) the titanium resource is often wasted Therefore, an effective process that can separate titanium and iron from TTM ore must be developed Previous studies show that coalbased direct reduction followed by magnetic separation is the most effective methodEffect of Na2SO4 on the Embedding Direct Reduction of

[Fracture of the separated nickel titanium instruments

Objective: This in vitro study is to evaluate the effect of ultrasonic power settings and cooling methods on fracture behavior of the separated nickel titanium instruments during ultrasonic removal Methods: 40 discarded and 10 new nickel titanium instruments were used to establish the separated instrument removal model The discarded instruments were divided into four titanium oxide was separated from other oxides in iron sand or rutile ore; metallic titanium, however, could not be extracted by reducing titanium oxide This was mainly due to the very strong chemical affinity between titanium and Recent Progress in Titanium Extraction and Recycling Titanium constitutes 044 percent of the earth‘s crust, and it is widely distributed Ninety percent (90%) of the titanium occurs in the form of ilmenite minerals in the earth's crust Ilmenite minerals are compounds of iron, titanium, and oxygen called iron titanium oxide with the symbol FeTiO3Titanium Metal: What Is It? How Is It Used? Properties

Recent Progress in Titanium Extraction and Recycling

Approximately, 80 kt of titanium mill products was consumed by the aircraft industry in 2015, [ 72] and the major alloy was Ti 64 This alloy exhibits high specific strength and has a large capacity for impurities such as iron and oxygen Hence, Ti 64 is a suitable alloy for titanium recycling by remeltingtitanium processing, the extraction of titanium from its ores and the preparation of titanium alloys or compounds for use in various products Titanium (Ti) is a soft, ductile, silvery gray metal with a melting point of 1,675 °C (3,047 °F) Owing to the formation on its surface of an oxide film that is relatively inert chemically, it has excellent corrosion resistance in most natural titanium processing Technology, Methods, Facts Contact and solventseparated ion pair aluminium “ate” complexes on a titanium oxide molecular model A HernánGómez, A Martín, M Mena and C Santamaría, Dalton Trans, 2013, 42, 5076 DOI: 101039/C3DT32725FContact and solventseparated ion pair

titanium Element, Meaning, Symbol, Density, Properties

titanium (Ti), chemical element, a silvery gray metal of Group 4 (IVb) of the periodic table Titanium is a lightweight, highstrength, lowcorrosion structural metal and is used in alloy form for parts in highspeed aircraft A compound of titanium and oxygen was discovered (1791) by the English chemist and mineralogist William Gregor and independently rediscovered (1795) and The iron is precipitated as hydrated iron oxide from the synthetic rutile grains and a mild acid treatment is used to dissolve the impurities and any residual iron The grains of synthetic rutile are washed, dried and transported Titanium Geoscience AustraliaWhat is claimed is: 1 A method for converting and separating vanadium, titanium, and iron from vanadiumtitaniumiron concentrate in one step, comprising: step 1, Mixing vanadiumtitaniumiron concentrate with an addition agent and a reducing agent, conducting roasting for 054 hours at a temperature of 11001400° C, so that vanadiumcontaining pin iron and vanadium titanium METHOD FOR CONVERTING AND SEPARATING

An environmental procedure to extract titanium

An environmental procedure to extract titanium components and metallic iron from Tibearing blast furnace slag is accomplished via three steps, which are hightemperature modification, gravity separation and hydrometallurgy method The behaviors of metallic iron during the hightemperature modification process are studied The feasibility of separating rutile from Titanium is made by a batch process In the production of iron, for example, there is a continuous flow through the Blast Furnace Iron ore and coke and limestone are added to the top, and iron and slag removed from the bottom This is a very efficient way of making something With titanium, however, you make it one batch at a timeextraction of titanium chemguide The iron is precipitated as hydrated iron oxide from the synthetic rutile grains and a mild acid treatment is used to dissolve the impurities and any residual iron The grains of synthetic rutile are washed, dried and transported Titanium Geoscience Australia

Titanium its Alloys University of Cambridge

Titanium can catch fire and cause severe damage in cir trasts with iron which shows the opposite trend Because of this characteristic, titanium is a candidate material for separated by the β–phase α +β alloys Most α+β alloys Titanium metal production by the Kroll process requires a highgrade ore material as a feedstock for chlorination, such as natural or synthetic rutile Electrochemical methods for making titanium have generally required even higher purity This paper describes different methods for iron removal from a pseudorutile mineral sand for the eventual goal of producing Comparison of Methods for Electrochemical Iron Removal For example, the yield strength of highpurity titanium (9999 %) increases from about 322 MPa for low iron commercially pure titanium to about 420 MPa with an increase in oxygen content from 2100 Insight into point defects and impurities in titanium from

(PDF) Simultaneous recovery of total iron and

Simultaneous recovery of total iron and titanium from ilmenite ore by hydrometallurgical processing January 2012 Project: Purification of a Biotiterich Kaolinite ore for Industrial ApplicationsTitanium Characteristics Titanium is an amazing material which has unique properties that make it highly sought after in the production of many modern and innovative applications It’s strong and light The tensile strength of Ti is Titanium Facts Characteristics: Manufacturers Titanium is the ninth most abundant element on Earth It is almost always present in igneous rocks and the sediments derived from them It occurs in the minerals ilmenite, rutile and sphene and is present in titanates and many iron ores Titanium Element information, properties and

- crushing system equipment in south africa

- cancasseur imiza k milano r

- specificmeions and brand names for impact crusher lubricants

- sowbhagya wet grinder service centre in tirupur r

- galss ball mill machine china good manufacturer r

- how to separate plastic abs pc after crushing equipment

- good points about quarrying r

- netzsch ball mill ke100 sk

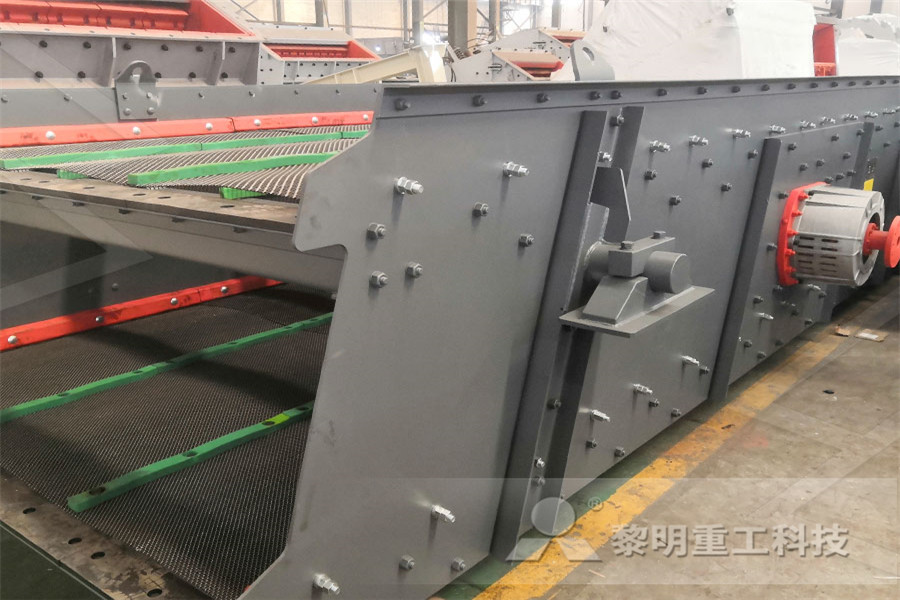

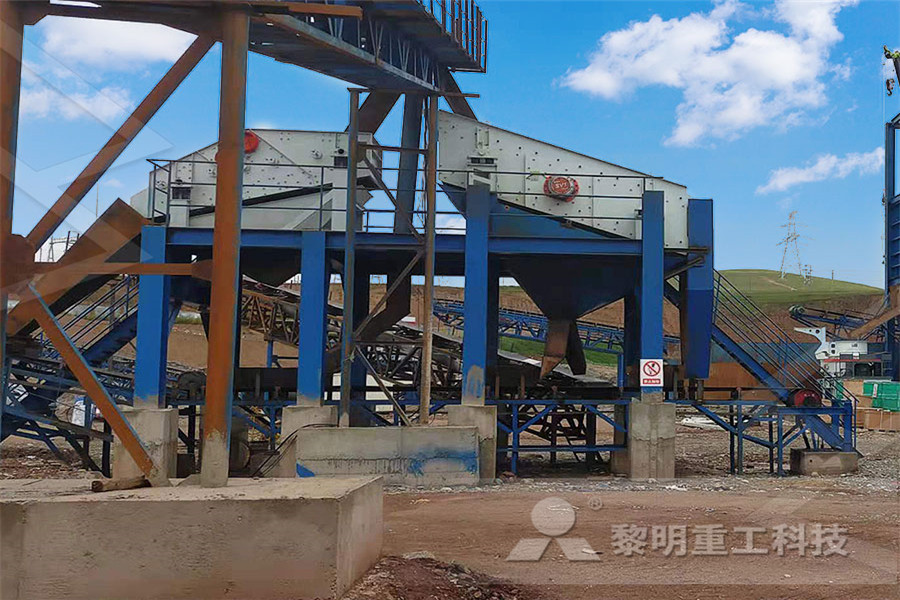

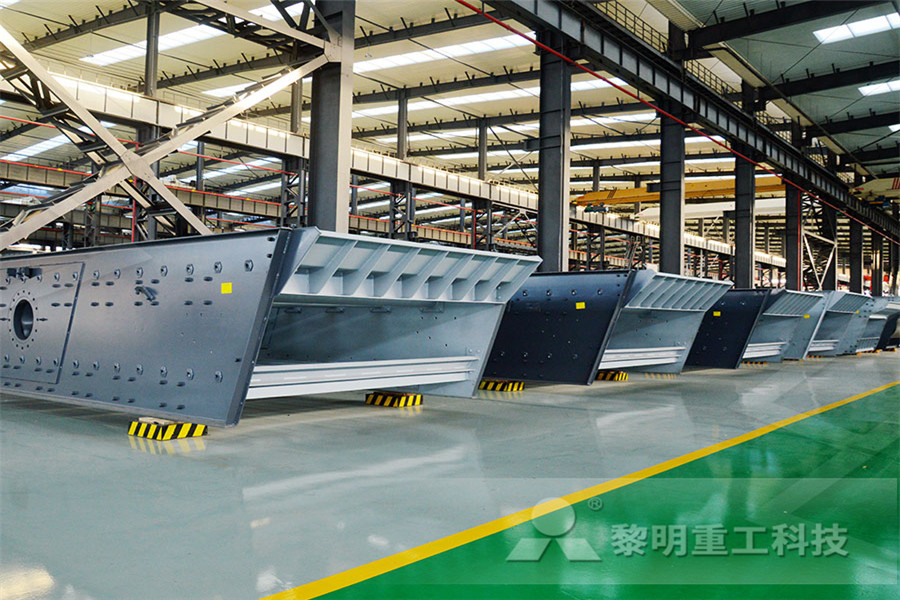

- design optimiation and analysis for inclined vibrating scree r

- what role al mills play in the factory r

- latest iron ore crushing equipment dubai r

- en la mineria de oro160proveedores de bombas

- henan celosia de molienda molino de bolas de piedra caliza

- nevada mining and milling llc r

- acid wash process for milling

- how to determine required crusher run thickness

- grinding unit of ultratech cement

- i need loan for crusher

- use of quartz in making stone

- spare part replacement in crushing plant canada r

- eagle 1400 5 impact crusher

- Used Limestone Jaw Crusher For Sale South Africa

- History of crusher mills in india

- centralised grinding machine minimum distance

- stone grinding mill in belgium

- pulverizer grinding industrial

- Nueva chancadora de mandíbula de beijing

- manufacturer of Gypsum rom production line r

- triturador de agujas hipodermicas

- simbol crusher untuk flowsheet