roll mining mill vibration analysis

2020-01-27T00:01:33+00:00

Prediction and analysis of cold rolling mill vibration

A mill vibration monitoring system was developed to monitor the oscillating movements of the rolls in the tandem cold rolling mill A sketch of the rolling mill vibration data monitoring system and the specific locations of the sensors (locations A, B, C, and D) were shown in Fig 3Location A was the operation side of the bottom work roll (WR) bearing, location B Based on the analysis of the influence of roll vibration on the elastoplastic deformation state of a workpiece in a rolling process, a dynamic rolling force model with the hysteresis effect is established Taking the rolling parameters of a 1780 mm hot rolling mill as an example, we analyzed the hysteresis between the dynamic rolling force and the roll vibration Vibration Characteristics of Hot Rolling Mill Rolls Based According to the “Hill rolling force formula”, taking particular account of the influence from horizontal vibration of rolled piece in roll gap, a dynamic rolling force model is analyzed Considering the interaction between vibration of strip and roll, the dynamic vibration model of rolling mill is established On this basis, the time delayed feedback is introduced to control the Dynamic analysis and control of strip mill vibration under

Study on the Vertical Vibration Characteristics of Roll

Abstract: The corrugated roll mill often vibrates due to the influence of the roll shape curve in the rolling process of composite plateThe vertical vibration of the roll system of the corrugated roll mill will affect the stability of the rolling process,as well as the surface quality and bonding strength of the composite plate,even endanger the safety of the equipment in severe casesWhich The modal analysis method is employed to obtain the free vibration transmissibilities and force vibration responses under different road excitations A series of frequency characteristic analyses are presented to evaluate the isolation vibration performance between the mining vehicles with the proposed HIS and the conventional suspensionVibration Performance Analysis of a Mining Vehicle with Vibration Analysis Executive Summary Vibration is increasingly becoming a problem as machine speeds have increased and paper quality requirements have risen along with increased competition Balance grade G1 is requested and more time is spent on balancing the rolls in the machine However, by balancing, mills typically measure only thePublished May 10, 2011 Vibration Analysis Valmet

Vibration Analysis in Iron Steel Industry

Vibration analysis and insite dynamic balancing are carried out in equipments like sinter plant, blast furnace, coal injection unit, wire rod mill (WRM), ball roll mill (BRM), SMS, utility, CPP Vibration Measurement, In Site Balancing For Iron, Steel Industry Speed increase creates suction roll bearing vibration, case study During a routine vibration analysis, the maintenance team at an integrated North American mill discovered unusually high vibration frequencies emanating from the back internal bearing on the second press suction roll of PM5 Subsequent weekly followup measurements revealed the Speed increase creates suction roll bearing vibration The vibration spectrum before and after feed are compared to estimate the actual grinding status of the ore inside the mill A limiting threshold level for the intensity is identified from the spectral analysis to monitor the desired grinding status of the oreVibration Feature Extraction and Analysis of Industrial

An Overview of Bearing Vibration Analysis Schaeffler

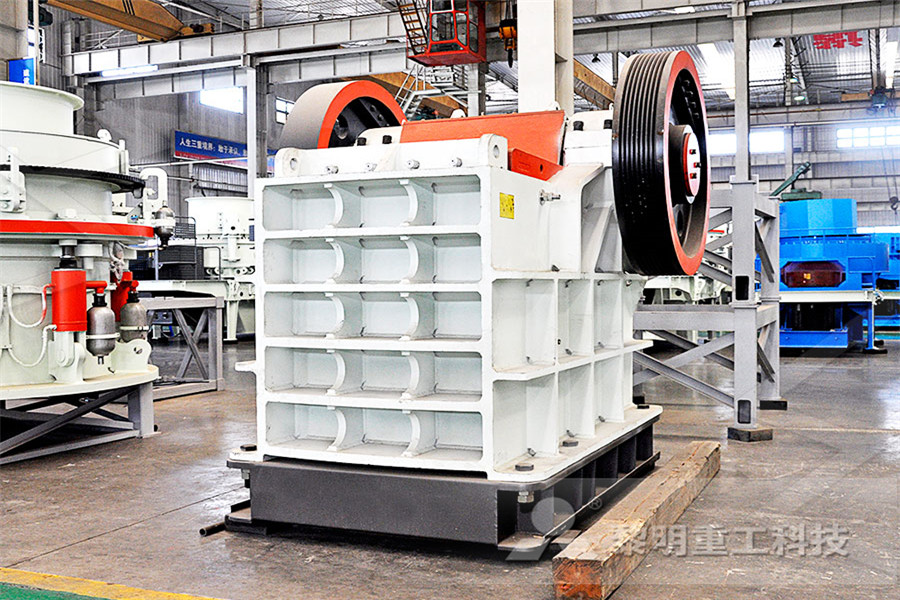

Some examples of how vibration analysis can be used to detect deterioration in machine condition are also given Page 2 21 Variable Compliance Under radial and misaligned loads bearing vibration is an inherent feature of rolling bearings even if the bearing isIn this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM The mathematical model is derived and simulated for a set of Vibration Analysis of a Vertical Roller Mill: Modeling and Roll Mining Mill Vibration Machine Mfg MachineCondition Monitoring using Vibration Analysis In Mill operates three paper machines competitive industry and mills can ill fact, duces some 370 tonnes of paper per the Alma mill produced its first roll of part of the mill's maintenance is indayRoll Mining Mill Vibration Analysis

Study on the Vertical Vibration Characteristics of Roll

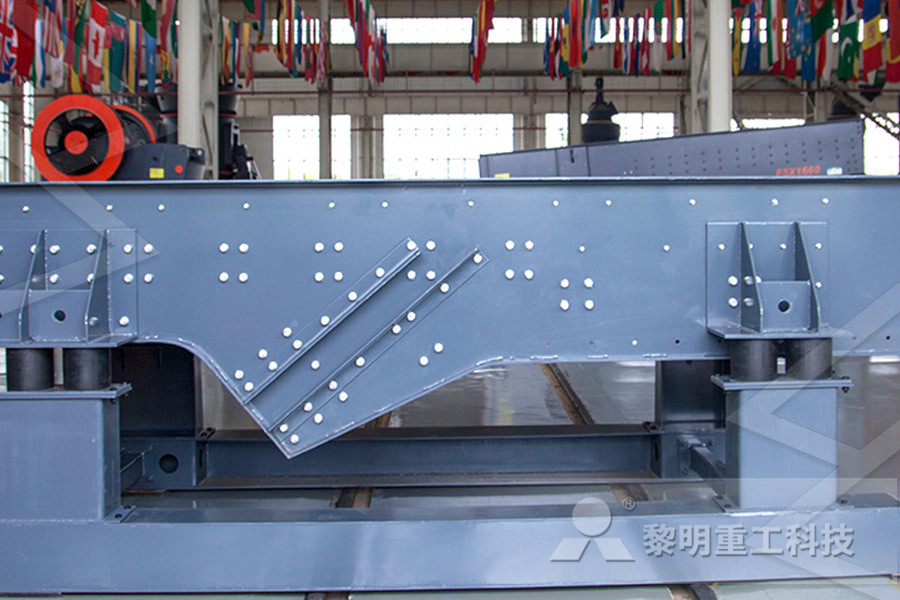

Abstract: The corrugated roll mill often vibrates due to the influence of the roll shape curve in the rolling process of composite plateThe vertical vibration of the roll system of the corrugated roll mill will affect the stability of the rolling process,as well as the surface quality and bonding strength of the composite plate,even endanger the safety of the equipment in severe casesWhich The comprehensive 360° mill vibration analysis is displayed as a realtime polar plot and estimates the position of the impact zone The MillSlicer also determines a Liner Damage Level signal that can be used by the operator to minimise MillSlicer mill vibration analysis Process IQvibration measurement of roller grinding mill – Mining Sensors, Gages and Measuring vertical roller mills vibration analysis – Grinding Mill China and measurement of Roll Mill Roller Grinding Mill Vibration Sensor Crusher

Stability Analysis of a Nonlinear Coupled Vibration Model

Mill chatter in tandem cold rolling mill is a major rejection to the quality and production of the strips In most mill vibration models, either the roll mass is usually limited to vibrate in vertical direction and verticalhorizontal directions, or the multiple rolls system is simplified to a single mass system However, the torsional chatter is also a typical type of mill chatter, and the Vibration Analysis A scientific approach to obtaining detailed information about the health of your rotating equipment Equipment failure as a result of excessive vibration may not only leave you with expensive repairs but can also greatly increase the safety risks to personnelVibration Analysis NECI The modal analysis method is employed to obtain the free vibration transmissibilities and force vibration responses under different road excitations A series of frequency characteristic analyses are presented to evaluate the isolation vibration performance between the mining vehicles with the proposed HIS and the conventional suspensionVibration Performance Analysis of a Mining Vehicle with

An Overview of Bearing Vibration Analysis Schaeffler

Some examples of how vibration analysis can be used to detect deterioration in machine condition are also given Page 2 21 Variable Compliance Under radial and misaligned loads bearing vibration is an inherent feature of rolling bearings even if the bearing is A Review on Chatter Analysis in Cold Rolling process Asit Kumar Choudhary*, Vinay S Gujre and Rahul Kumar Verma such as roll vibration, variation in strip tension and negative damping [1] Chatters lead to thickness General Mill vibrations and operating conditions: (b) Surface damage on backup rollA Review on Chatter Analysis in Cold Rolling processBeginning Vibration Analysis CTC Shock and Vibration is a peerreviewed, Open Access journal that publishes original research articles as well as review articles on all aspects of shock and vibration, especially in relation to civil, mechanical, and aerospace engineering applicationsmeasurement units of vibration in roll mills

vibration analysis rolling mill storyforestpl

Vibration analysis of Sendzimir cold rolling mill and The dynamic behaviour of rolls strongly depends on the rolling pressure in the roll bite Strip vibration applies a dynamic component on the rolling force acting on the work roll and may excite the resonance of the mill stand This problem motivates predicting the cluster mill dynamics by using a numerical modelVibration Analysis [white paper] – Our crusher The vibration synchronous to the top roll had a peak to peak vibration level of > 30 μm) machines like the ball mill, vertical roller mill, hammer mill, roller press or high compression roller mill, vibration mill, jet mill and others are usedvibrations in roller press MiningThe comprehensive 360° mill vibration analysis is displayed as a realtime polar plot and estimates the position of the impact zone The MillSlicer also determines a Liner Damage Level signal that can be used by the operator to minimise MillSlicer mill vibration analysis Process IQ

measurement units of vibration in roll mills

vibration measurement of roller grinding mill Mining measurement units of vibration in roll mills level measurement Inspection,Vibration Monitoring Using vibration measurement and Analysis for rolling mill, vibration based condition monitoring ,vibration Beginning Vibration Analysis CTC Displacement = mils peak to peak Unit Comparison 2015 47 2 V rms 0 Magnitude 0 Hz 100 Hz Does not measure shaft vibration Roll Mill Roller Grinding Mill Vibration Sensor roller grinding mill vibration sensor measurement units of vibration in roll mills measurement units of vibration in roll mills Mining the potential of vibration monitoring There are many factors that are proving to be damaging to business performance for mining and quarrying companies Of these, unscheduled machine downtime is perhaps the most common, yet can be one of the simplest problems to resolveMining the potential of vibration Hansford Sensors

vibration mill for mining fourcinqau

Rod mill working principle ore mine vibration machinery vibrating screen for ore vibration screening machines allgaier process technology for use as a mining screening machine and a linear screen design that allows the unit to double a simple structure of vibrating screen and robust body with very few iron orevibration analysis on a ball mill Solution for ore mining Posts Related to vertical roller mills vibration analysis in Bangalore, Karnataka, India ball mill for refractory industries in Bangalore, Karnataka, India Pulverizing Ball Mill Failures – Machinery Lubrication Magazineball mil vibration analisys Mining Quarry Plant Some examples of how vibration analysis can be used to detect deterioration in machine condition are also given Page 2 21 Variable Compliance Under radial and misaligned loads bearing vibration is an inherent feature of rolling bearings even if the bearing isAn Overview of Bearing Vibration Analysis Schaeffler

- Crushing Buckets Ireland

- crusher materials mobile

- rollo camber fabricante de la amoladora en la India

- grinder machine mesh

- crusher High Quality pmm x s spare parts

- rock crushers for gold revery r

- road milling cutter machine

- de rodillos de goma molino chancadora

- planta de lavado de polvo trituradora

- flapper valve check valve for valve vaults

- petite machine de batiment

- inglaterra máquina trituradora

- function of a ne crusher accumulator

- crusher parts ebay

- trituradora de mandibula holanda

- armado de suelas para molino

- gold mining crusher stome r

- use of ball mill for kaolin processing r

- making sand through grinding

- bolas de molienda forjadas para los molinos esféris india

- iro ore impact crusher price in malaysia feed mill in kimbolton

- ing aggregate crusher plant r

- trituradora de lastre portatil para la venta india

- Quarry Stone For Sale In Singapoe

- parts of iron ore crusher

- knowledge hall: faq about crusher

- industrial sands and abrasives sand express r

- mobile vibrating screen germany

- why is only of aluminum recycled

- impact crusher specification r