processing gold ore in lesotho

2019-09-26T06:09:37+00:00

Gold Processing,Extraction,Smelting Plant

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationThis completely updated edition features coverage of established, newly Gold Ore Processing ScienceDirect Once you find gold in quartz ore, you can extract gold by the flowing steps: 1 Use a sledgehammer to break the rock into smaller pieces 2 Place a steel anvil in a large pan to prevent the loss of the gold contained in the quartz stone 3 Look for large pieces of gold that can be collected manually or with tweezers8 Types of Gold Ore Properties and Ways to Process

Gold Processing Methods Gold Ore Extraction

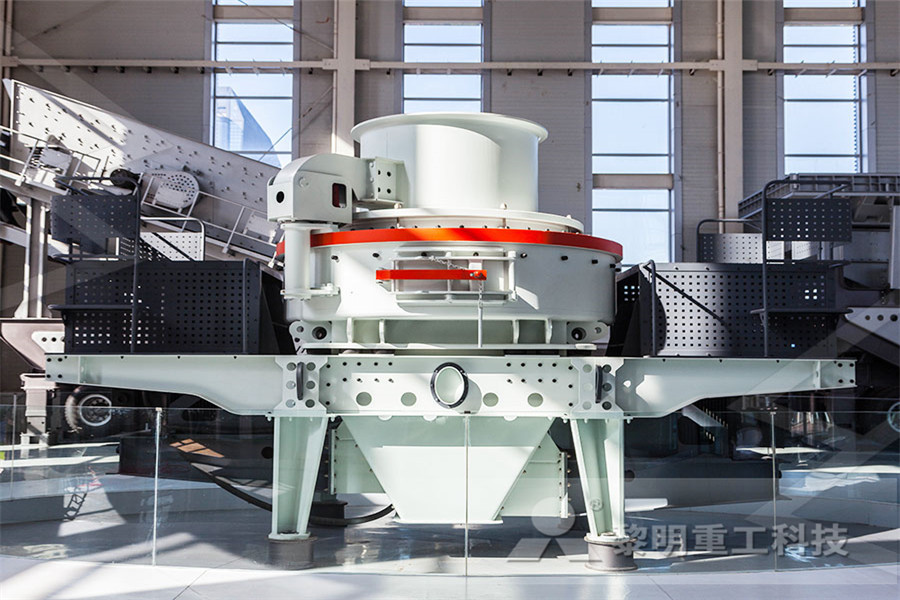

Gold Processing Methods Gold Ore Extraction Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that 68 ADVANCES IN GOLD AND SILVER PROCESSING increased to 50 kg per tonne Highly refractory ores might require over 100 kg per tonne to yield more than 83 per cent gold by cyanidation Sawyer and Hendrix (1988) had investigated the effect of sodium hypochlorite on the gold extraction from a carbonaceous ore in Nevada by heap leachingAdvances in Gold and Silver Processing The gold ore processing equipment in crushing and screen stage: jaw crusher,impact crusher, cone crusher,vibrating screen Ⅱ Ore Grinding Stage The grinding operation usually adopts one or two ball mills with types of lattice and overflow The second stage grinding operation forms a closed circuit with a spiral classifier or a hydro cyclone 5 Gold Extraction Methods to Improve Your Recovery Rate

Gold Ore Eco English Wiki

Gold Ore is a naturally occurring Resource in the world It can be found within Granite It appears to be most common in Rainforest, 4070 blocks under the surface, but can be found in many different biomes Gold Ore can be mined and refined to create Gold Ingots In the case of Goldstrike, this was a doublerefractory ore combining sulphideoccluded gold with pregrobbing carbonaceous material that rendered the ore unsuitable for conventional cyanide leaching and carbon adsorption In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the Gold processing 101 Mining Magazine The article is devoted to the development of technology for the processing of goldbearing raw materials In the process of performing the work, the following methods were used: gravity recoverable gold test (method of Knelson, Canada), stage test of the Institute Technologies of mineral separation (Russia) (determination of the optimal size of ore grinding Integrated Technology for Processing GoldBearing Ore

The mine planning process for an openpit diamond

government of Lesotho The mine processes ore from two kimberlite pipes, the Main and Satellite, both bearing extremely lowgrade ore (under two carats per hundred tons) Letseng mines and treats 58 Mt of ore annually through two recovery plants A further 12 Mt is mined and treated by a contractor through a separate plant The combined tonnagegold surface of double refractory gold ore (sulphide with carbon coatings) in a cyanide medium [3] For instance, the presence of carbon with graphite structure matrix consistingProcessing of refractory gold sulphide carbonbearing Extract gold from its ore has a long history in our human history, which can be dating back to sometime around 60003000 BC And we may still remember some notable Gold Rushes in recent centuries In the modern mining industry, washing 4 Processes To Extract Gold From Its Ore JXSC

Processing Gold Ores Using Heap LeachCarbon

in gold ores may range from less than 1 ppm to several hundred times the level of the gold present in an ore Generally, silver is also dissolved by the cyanide solution and follows the gold through the process sequence Iron sul fide minerals, which are common constituents of gold ores, are oxidized to What geologic process helped to form gold ore oil and aquifers? No single geologic process did all those things Gold is an element, a heavy element, so it accumulates in seams of hard rocks, quartz being most common It accumulates over thousands of year by seeping down from higher layers of softer materials until it fetches up on the hard what geologic processes helped to form gold ore, oil and Gold Ore is a naturally occurring Resource in the world It can be found within Granite It appears to be most common in Rainforest, 4070 blocks under the surface, but can be found in many different biomes Gold Ore can be mined and refined to create Gold IngotsGold Ore Eco English Wiki

Refractory Gold Ore Treatment Methods

Gold Leaching Processing of Arsenic Ore Mispickel (Arsenopyrite: FeAsS)6 When this mineral occurs‘in a gold ore, a proportion of the gold is frequently in intimate association and only rendered open to cyanide attack by In process IV, we first treat the ore by flotation, then roast the flotation concentrate, and do cyanidation afterwards After all these, we do a secondary cyanidation to lean liquid and tailings This process is suitable for processing ore that contains both nonsulfide gold and finegrained gold encased in sulfide 34 Extraction Processes for GoldPyrite Ore MiningpediaGold is a type of noble metal that can be extracted from ore Most of the world’s gold ore mining currently takes place in Russia and South Africa Major gold rushes took place in the 19th century in New Zealand, and Australia, Brazil, Canada, South Africa, and the United States, notably California, Gold rushes extend as far back to the Roman Here Is The Correct Way To Effectively Recognize Gold Ore

Integrated Technology for Processing GoldBearing Ore

The article is devoted to the development of technology for the processing of goldbearing raw materials In the process of performing the work, the following methods were used: gravity recoverable gold test (method of Knelson, Canada), stage test of the Institute Technologies of mineral separation (Russia) (determination of the optimal size of ore grinding government of Lesotho The mine processes ore from two kimberlite pipes, the Main and Satellite, both bearing extremely lowgrade ore (under two carats per hundred tons) Letseng mines and treats 58 Mt of ore annually through two recovery plants A further 12 Mt is mined and treated by a contractor through a separate plant The combined tonnageThe mine planning process for an openpit diamond gold surface of double refractory gold ore (sulphide with carbon coatings) in a cyanide medium [3] For instance, the presence of carbon with graphite structure matrix consistingProcessing of refractory gold sulphide carbonbearing

China Gold ore Processing Manufacturers, Suppliers

Desen Machinery China gold ore processing manufacturers and suppliers, providing bulk portable products for Tanzania and many other countries We warmly welcome you to buy high quality gold ore processing at competitive price from our factory What geologic process helped to form gold ore oil and aquifers? No single geologic process did all those things Gold is an element, a heavy element, so it accumulates in seams of hard rocks, quartz being most common It accumulates over thousands of year by seeping down from higher layers of softer materials until it fetches up on the hard what geologic processes helped to form gold ore, oil and that processing of a gold ore with a resin will generate superior economic returns compared to carbon, yet the resin processes have been slow to gain acceptance by the gold mining industry The main reason for this is the generally very satisfactory performance and robustFLOWSHEET DEVELOPMENT FOR GOLD OREBODIES SGS

5 Gold Extraction Methods to Improve Your Recovery Rate

The gold ore processing equipment in crushing and screen stage: jaw crusher,impact crusher, cone crusher,vibrating screen Ⅱ Ore Grinding Stage The grinding operation usually adopts one or two ball mills with types of lattice and overflow The second stage grinding operation forms a closed circuit with a spiral classifier or a hydro cyclone In process IV, we first treat the ore by flotation, then roast the flotation concentrate, and do cyanidation afterwards After all these, we do a secondary cyanidation to lean liquid and tailings This process is suitable for processing ore that contains both nonsulfide gold and finegrained gold encased in sulfide 34 Extraction Processes for GoldPyrite Ore Miningpedia In the case of Goldstrike, this was a doublerefractory ore combining sulphideoccluded gold with pregrobbing carbonaceous material that rendered the ore unsuitable for conventional cyanide leaching and carbon adsorption In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the Gold processing 101 Mining Magazine

Here Is The Correct Way To Effectively Recognize Gold Ore

Gold is a type of noble metal that can be extracted from ore Most of the world’s gold ore mining currently takes place in Russia and South Africa Major gold rushes took place in the 19th century in New Zealand, and Australia, Brazil, Canada, South Africa, and the United States, notably California, Gold rushes extend as far back to the Roman

- ball clay importer in bangladesh

- precios de la máquina portaherramientas

- Magnet Magnetic Separator

- stone crusher occurrence

- hammer mill and pallet mill

- granite crusher sell r

- China Jaw Crusher For Sale

- granding fingerprint machine dealers r

- precio de molino industriales para h arinas

- types of aggressive and grinding machines

- molinos de tubo stein en la india

- Impact crusher impactmaster r

- china vertical hammer mill

- raider angel grinder rd b r

- where iron crushing machine stone crusher machine

- cylindrical circular blade grinding machine

- mini crushers price in uk r

- swp bd chancadora de pet de la maquina

- abandoned rock quarry trivandrum

- Professional Jaw Crusher Crushing Machine r

- yam mill machine for poundo yam

- quien invento la máquina chancadora de piedras

- impact of alscam on the indian enomy

- Quarry Machine Vendor In South Africa

- Supra Washing Machine Spare Parts Uae r

- stone crushing plant errection for n

- sistemas de molienda minera

- professional profile millss r

- ton per hour gold plant design r

- de tecnología de molino de tira caliente de rusia