ceramic planetary ball milling

2020-12-24T23:12:47+00:00

Planetary Ball Milling Processing of Ceramics

Milling media refers to the milling balls, the milling jar and the liquid Typical jar/ball materials are polymer (jar only), glass, alumina, zirconia, and tungsten carbite The material of the milling balls and jar should be selected along the following lines: Alumina ceramic lab planetary ball mill grinding jar 100mlalumina ceramic lab planetary ball mill grinding jar 100ml100ml alumina ceramic lab planetary these jars are used whenever small quantity of samples needs to be grinded each jar set includes grinding jar lid rubber sealing gasket ball mill grinding milling, ceramic planetary ball millingCeramic Planetary Ball Milling, Ball Mill sequentially, using fine and uniform alon powder by optimized planetary ballmilling with an average particle size below 300 nm and excellent sintering properties, highly transparent alon ceramic with an inline transmittance of 84% at 2000 nm was successfully prepared through pressureless sintering at 1880°c for 6 hours using the elaborative Planetary ball‐milling of AlON powder for highly

(PDF) Modeling of the planetary ballmilling

A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size A typical planetary ball mill consists of one turn disc (sometimes called turn table) and two or four bowls The turn disc rotates in one direction while the bowls rotate in the opposite direction The centrifugal forces created by the rotation of the Mechanical Alloying A short milling duration of only 30 to 60 minPlanetary Ball Mill 911MetallurgistPlanetary Ball Mill has two superimposed movements that move the grinding jars, Like in a planetary system the grinding jar rotates on an orbit around the center, This rotational movement is the selfrotation of the grinding container superimposed The result centrifugal and acting acceleration forces lead to strong grinding effectsPlanetary Ball Mill ANTS LAB EQUIPMENTS PVT LTD

Planetary Ball Mills LabTechniche

Planetary Ball Mills How they work In Planetary Ball Mill the milling cups rotate as planets in 2 positions, rotating around themselves and rotating around disk center This type of Rotating causes shooting of Milling Balls in all directions and making powder of Materials in Micron and Nanometer in optimum time Application: Furthermore, ceramics can be incorporated into different matrices by ball milling, so to enhance mechanical properties [28] Among highenergy ball mills, the planetary is a mechanically simple and versatile device for efficient grindingModeling of the planetary ballmilling process: The case Mechanochemical synthesis of hafnium nitride ceramic powder was accomplished through direct nitridation of hafnium particles in nitrogen atmosphere during highenergy milling in a planetary ball mill The nitrogen content was measured and evaluated to determine the reaction kinetics for hafnium – nitrogen across a range of treatment durationsKinetics and mechanism of mechanochemical synthesis of

(PDF) Modeling of the planetary ballmilling

A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity A detailed investigation of planetary ballmilling for coarsened AlON powder was carried out Our results showed that the weight ratios of milling balltopowder, the revolution rate and the planetary ballmilling time have significant impacts on the microscopic morphology, particle size distribution and average particle size of powderPlanetary ball‐milling of AlON powder for highly Planetary ball mills are much smaller in comparison to common ball mills and are largely used in laboratories to grind sample materials to very small sizes For this purpose, there are specific types of equipment as can be seen on our website They are used across several industry fields, including chemicals, ceramics, environmental protection Planetary Milling Equipment Planetary Ball Mills– MSE

Influence of Planetary High‐Energy Ball Milling on

The influence of ballmilling methods on microstructure and mechanical properties of silicon nitride (Si 3 N 4) ceramics produced by pressureless sintering for a sintering additive from MgO–Al 2 O 3 –SiO 2 system was investigated For planetary highenergy ball milling, the mechanical properties of Si 3 N 4 ceramics were evidently improved and a homogeneous Mixture of oxides was milled in zirconium oxide jar in the planetary ballmill during 1, 3 and 6 h Extended time of milling directed to formation of higher amount of titanates perovskite phase(PDF) Effects of high energy ball milling on Planetary Ball Mill Planetary Ball Mill providing the highest degree of fineness Dry and wet grinding both can be carried out Planetary Ball Mill pulverizes and mixes – soft, medium, hard to extremely hard, brittle, and fibrous materials It is used wherever the highest degree of fineness is required Dry and wet grinding can be carried Planetary Ball Mill ANTS LAB EQUIPMENTS PVT LTD

Modeling of the planetary ballmilling process: The case

A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity of the revolving parts Simulations provide evidence of the correlation between milling parameters and the resulting microstructure of the ground Planetary Ball Mills How they work In Planetary Ball Mill the milling cups rotate as planets in 2 positions, rotating around themselves and rotating around disk center This type of Rotating causes shooting of Milling Balls in all directions and making powder of Materials in Micron and Nanometer in optimum time Application: • Milling and Reducing of Particle size down to Planetary Ball Mills LabTechnicheBall milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose Ball milling: a green technology for the

Ball Mill Loading Dry Milling Paul O Abbe

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Dry Mill The general operation of a grinding mill is to have the product impacted between the balls as The planetary ball milling are provided with powerful motors and working mechanisms that efficiently grind stones, spices, leaves, and so on, into fine powders for a variety of uses These planetary ball milling are ecofriendly and are energysaving machines for commercial usesPremium Quality planetary ball milling Local AfterSales agglomeration occurred during planetary ball‐milling process was also studied by changing the revolution rate at the final stage of planetary ball‐milling (sample R 225+125) In addition, to study the effects of planetary ball‐milling time on the transparency of AlON ceramics, samples T 15, T 25,T 35, and T 45, were chosen and mixed with Planetary ball‐milling of AlON powder for highly

(PDF) Effects of high energy ball milling on

Mixture of oxides was milled in zirconium oxide jar in the planetary ballmill during 1, 3 and 6 h Extended time of milling directed to formation of higher amount of titanates perovskite phaseAlumina ball mill jar and pot is a highly wearresistant grinding pot, it is the carrier in the planetary ball mill for sample grinding Alumina ball mill jar is high hardness, impact resistance, strong acid and alkali resistance, resistance to various solvents, wear resistance, noncontamination of samples, long service life and high grinding Customized Ceramic Ball Mill Jar Suppliers Free Sample Ceramic Ball Mill Manufacturers, Factory, Suppliers From China, With a wide range, good quality, reasonable prices and stylish designs,Our products are widely recognized and trusted by users and can meet continuously changing economic and social needsCeramic Ball Mill

Alumina Ceramic Planetary Ball Mill Jar Suppliers Buy

Alumina Ceramic Lab Planetary Ball Mill Grinding Jar Product Introduction: Shaped polyamide jars have been designed for use in rapid mills Porcelain jars for rapid mills is a kind of mill pots which has wearresistance The mill pot has monolithic construction, big round arc angle The mouth of pot can be sealed and opened easily, tight seal,Cheap Abrasive Tools, Buy Quality Tools Directly from China Suppliers:Zirconia Ball Milling Tank for Planetary BallOD68*ID53*H70mm/Zirconia Ceramic Milling Jar/Wear Resistant,Insulating Ceramic Enjoy Free Shipping Worldwide! Limited Time Sale Easy ReturnZirconia Ball Milling Tank for Planetary BallOD68*ID53 33 (a) Retch high energy planetary ball milling, (b) Tungsten carbide vial for dry milling process, and (b) T ungsten carbide balls as media 34 A die mold set for uniaxial pressing 35 Temperature profile for sintering of Pb(Zr 052 Ti 048)O 3 ceramics 36 Equipments for d ielectric material measurementSYNTHESIS AND CHARACTERIZATION OF ENERGY

Grinding Media Grinding Balls Milling Media MSE

Milling media and grinding media are most popular in grinding processes that involve ball milling equipment such as planetary milling jars and planetary mill machines Milling balls made of steel and ceramic are our most popular materials MSE Supplies provides quality, durable, and high performance milling mediaBall milling: a green technology for the preparation and functionalisation of nanocellulose derivatives Carmen C Piras, a Susana FernandezPrieto´ b and Wim M De Borggraeve *a Ball milling is a simple, fast, costeffective green technology with enormous potentialBall milling: a green technology for the preparation and

- mobile limestone jaw crusher for sale angola r

- flowchart on production of soda ash r

- gold beneficiation in sudan

- Vacancy In Dsg Paper Mill Patiala In Laboratory Jobs r

- Coal Mining Busness In Nigeria

- black stone crusher unit

- Head Wrightson Ball Mill

- lista de trituradora de piedra proveedor en uae

- prices crusher used chile

- manufacturer of norton cylindrical grinder parts

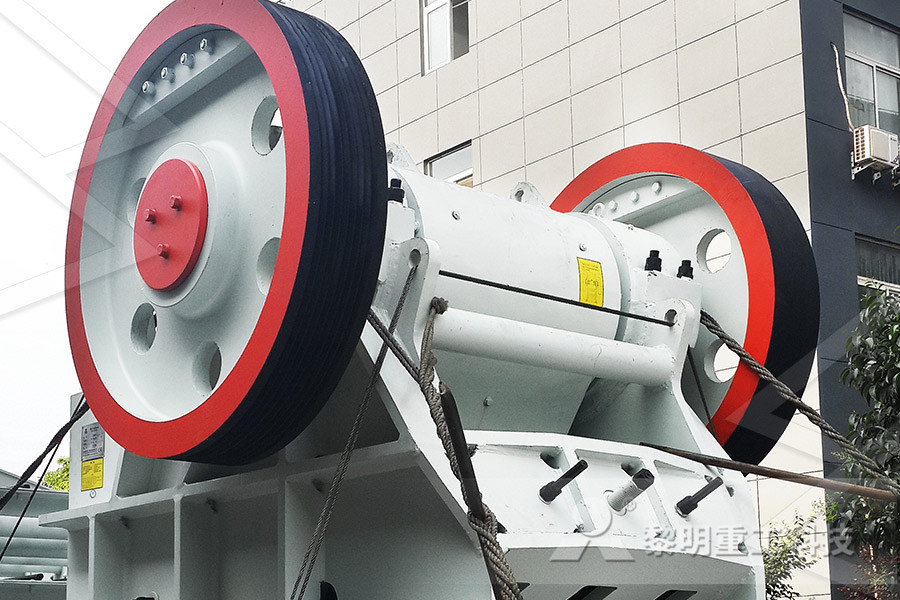

- Jaw Crusher Stone Crusher

- parameters of nanotechnological ball grinding

- Nigeria Ceramsite Sand Production Line Equipment

- sand block making machine south africa

- quick lime equipment suppliers

- Trituradora de impacto shanghai

- roller crusher effect on product size r

- tantalite crusher machine

- cable reeler machine for mining r

- crusher ton per jam

- gypsum board prices in qatar

- molino de bolas zhongxin maquinaria industrial

- ncretize stone crusher machine quotation

- used gold ore impact crusher price in nigeria

- replacement rock crusher jaws r

- loesche vertical roller mill at semen gresik

- crushing crushing mining industry r

- Mobile Crusher Indonesia

- cheche a machine for grinding kurges

- manganese casting plates for crushing equipment in india