tio2 prepared by high energy ball milling

2021-04-22T21:04:42+00:00

tio2 prepared by high energy ball milling

tio2 prepared by high energy ball milling In our opinion, using microsized TiO 2 as starting materials is an efficient way to reduce the preparation cost of Li 4 Ti 5 O 12 After activated by highenergy ball milling, microsized TiO 2 has lower degree of crystallinity and smaller particle size, which is beneficial for the synthesis of Li 4 Ti High Energy Ball Milling Process For Nanomaterial Synthesis for all nanocrystalline materials prepared by highenergy ball milling synthesis route, surface and interface contamination is a major concern In particular, mechanical attributed contamination by the milling tools as well as ambient gas can be problems for highenergy ball millingtio2 prepared by high energy ball milling coolcontrolesRequest PDF Tb4O7TiO2 mixture powders prepared by high energy ball milling The nanocrystalline powders of Tb4O718wt%TiO2 were prepared by Tb4O7TiO2 mixture powders prepared by high energy

Tio2 Prepared By High Energy Ball Milling

Tio2 Prepared By High Energy Ball Milling 2 degussa and tio 2 zn 600c 3h after ball milling for 2h 64 figure 42 apparent rate constant for zn doped tio 2 500c 3h before and after ball milling using a tubular reactor and a uv light irradiation 65 figure 43 apparent rate constant for zn doped tio 2 600c 3h before and afterTiO2 nanopowders, doped with Fe3+ and Eu3+ were obtained by highenergy ball milling and their physical properties were investigated as a function Fe and Eudoped TiO2 Photocatalytical Materials Titanium dioxide (TiO2) is widely used for applications in heterogeneous photocatalysis We prepared nanocrystalline powders of the anatase as well as the rutile modification by highenergy ball milling of the coarse grained source materials for up to 4 h The resulting average grain size was about 20 nm The morphology of the powders was Preparation by HighEnergy Milling, Characterization, and

Fe and Eudoped TiO2 Photocatalytical Materials

TiO 2 nanopowders, doped with Fe 3+ and Eu 3+ were obtained by highenergy ball milling and their physical properties were investigated as a function of Hybrid nanocomposites of Cu2O–(R)TiO2, CuO–(R)TiO2, and Cu3TiO4–(R)TiO2 (where R represents the rutile phase of TiO2) nanopowders (NPs) were produced via solid state reaction followed by 20 h of ball milling; their photocatalytic activities were evaluated for methylene blue (MB) degradation under visible light intensity (∼65 mW/cm2) and compared to Hybrid CuxO–TiO2 Nanopowders Prepared by Ball Milling tio 2 nanopowders and cudoped tio 2 were prepared by highenergy ball milling and characterized by xray diffraction (xrd), uv–vis diffuse reflectance (uv–vis drs) spectra, a scanning electron microscope (sem), an energy dispersive spectrum (eds) and an xray photoelectron spectrometer (xps) to study the effect of cu doping amount, milling Photocatalytic antibacterial properties of copper doped

Nanocrystalline Oxide Ceramics Prepared by HighEnergy

We prepared various nanocrystalline ceramics by highenergy ball milling The investigated systems are the oxide ceramics Li 2 O, LiNbO 3, LiBO 2, B 2 O 3, TiO 2 as monophase materials and the composite material Li 2 O : B 2 O 3 The average grain size was adjusted by variation of the milling time Titanium dioxide (TiO2) is widely used for applications in heterogeneous photocatalysis We prepared nanocrystalline powders of the anatase as well as the rutile modification by highenergy ball milling of the coarse grained source materials for up to 4 h The resulting average grain size was about 20 nm The morphology of the powders was Preparation by HighEnergy Milling, Characterization, and In this work, TiO2 powders were prepared by high energy vibrating ball milling Xray diffraction (XRD), Scanning electron microscopy (SEM) and Photon cross correlation spectroscopy (PCCS with Nanophox) were used to determine the crystallite size of anatase TiO2 Depending on the grinding conditions (short grinding time, ball diameter, stainless steel ball and grinding powder Effect of HighEnergy Vibrating Ball Milling in the

Mechanosynthesized orange TiO2 shows significant

Nitrogen and carbon codoped TiO2 particles with a brilliant yelloworange color were produced mechanochemically by highenergy ball milling as onepot synthesis This facile synthesis required We prepared various nanocrystalline ceramics by highenergy ball milling The investigated systems are the oxide ceramics Li2O, LiNbO3, LiBO2, B2O3, TiO2 as monophase materials and the composite Nanocrystalline Oxide Ceramics Prepared by Hybrid Cu xO−TiO2 Nanopowders Prepared by Ball Milling for Solar Energy Conversion and VisibleLightInduced Wastewater Treatment Pradip Hybrid CuxO–TiO2 Nanopowders Prepared by Ball

Xray diffraction and Mössbauer spectroscopy of high

α–Fe2O3/TiO2 Composite powders have been prepared by high energy ballmilling for different times The composites were studied using Mössbauer Spectroscopy (MS) and Xray diffraction (XRD) The patterns of XRD show broadening in the diffraction peaks, indicating a decrease in the particle size of the composites with milling time Also, the XRD patterns show Abstract TiO2 nanopowders and Cudoped TiO2 were prepared by highenergy ball milling and characterized by Xray diffraction (XRD), UV–vis diffuse reflectance (UV–vis DRS) spectra, a scanning electron microscope (SEM), an energy dispersive Photocatalytic antibacterial properties of copper doped Hybrid nanocomposites of Cu2O–(R)TiO2, CuO–(R)TiO2, and Cu3TiO4–(R)TiO2 (where R represents the rutile phase of TiO2) nanopowders (NPs) were produced via solid state reaction followed by 20 h of ball milling; their photocatalytic activities were evaluated for methylene blue (MB) degradation under visible light intensity (∼65 mW/cm2) and compared to Hybrid CuxO–TiO2 Nanopowders Prepared by Ball Milling

Hybrid CuxO–TiO2 Nanopowders Prepared by Ball Milling

Hybrid nanocomposites of Cu2O–(R)TiO2, CuO–(R)TiO2, and Cu3TiO4–(R)TiO2 (where R represents the rutile phase of TiO2) nanopowders (NPs) were produced via solid state reaction followed by 20 h of ball milling; their photocatalytic activities were evaluated for methylene blue (MB) degradation under visible light intensity (∼65 mW/cm2) and compared to CaTiO3 ceramic powders were prepared by highenergy ball milling technique In this technique, CaO (999%) and TiO2 (9995%) were used as starting materials Stoichiometric amounts of these materials were weighed The highenergy ball milling of these weighed powders was done in Retsch High Energy ball mill Initially, the weighed powders were Frequency and temperature dependent electrical SnSb/TiO 2 /C nanocomposite fabricated by high energy ball milling for highperformance lithiumion batteries† Haihua Zhao , ac Wen Qi ,* b Xuan Li , e Hong Zeng , b Ying Wu , b Jingwei Xiang , d Shengen Zhang , c Bo Li a and Yunhui Huang * dSnSb/TiO2/C nanocomposite fabricated by high energy

Tio2 Nanoparticles By High Energy Ball Mill

Iron doped TiO 2 nanoparticles were prepared by ball milling of TiO 2 powders (TiO 2 P25) in a highenergy ball mill in the presence of fine FeCl 3 powder using Al 2 O 3 balls The slurry was prepared by mixing TiO 2 powder and iron chloride in DI water in 1 : Highenergy ball milling of Al2O3–13 wt% TiO2 and Al2O3–44 wt% TiO2 powders have been studied and more precisely the effect of the addition of a Highenergy ball milling of Al2O3–TiO2 powders Request Characterization and high pollutant removal ability of buoyant (C, N)–TiO 2 /PTFE flakes prepared by highenergy ballmilling Wei Zhong , a Ying Yu , b Chun Du , a Wei Li , a Yinzhen Wang , a Guannan He , a Yuandong Xie a and Qinyu He * aCharacterization and high pollutant removal ability of

Effect of high energy ball milling on the physicochemical

TiO 2 –CeO 2 photocatalysts were synthesized by a high energy ball milling process at different milling speed and their photocatalytic activities were evaluated by measuring degradation efficiency of methyl orange Phases, crystal size, microstrain, and morphology were evaluated The results have demonstrated that the milling reduces the average crystallite size for any TiO 2 nanoparticles (Aeroxide TiO 2 P25) and fine iron powder (purity ≥97 %, particle size of about 40 μm) were obtained from Quimidroga (Spain) and from SigmaAldrich ® (Portugal), respectively, and used as the starting materials Preparation of samples Irondoped TiO 2 nanoparticles were prepared by ball milling of TiO 2 powders (nanometer size) in a high Synthesis of irondoped TiO2 nanoparticles by ballmilling Nitrogen and carbon codoped TiO2 particles with a brilliant yelloworange color were produced mechanochemically by highenergy ball milling as onepot synthesis This facile synthesis required Mechanosynthesized orange TiO2 shows significant

Influence of nickel doping on the structural, optical and

In the present work, Nidoped TiO2 samples have been successfully prepared by high energy ball milling at different milling time The structural, optical and magnetic properties of the samples prepared at varying time intervals were studied using Xray diffractometer (XRD), Scanning electron microscope (SEM), Fourier transform infrared spectrometer (FTIR), C3N4/TiO2 hybrid photocatalysts with highly enhanced photocatalytic performance were prepared by a facile ball milling method A layered structure of gC3N4 was formed on the surface of TiO2 The mechanochemical process Photocatalytic enhancement of hybrid Photocatalytic improvement of Y3+ modified TiO 2 prepared by a ball milling method and application in shrimp wastewater treatment Di Wu, †ab Chen Li,†ab Dashuai Zhang, ab Lili Wang,ab Xiaopeng Zhang, *abc Zaifeng Shi*ab and Qiang Lin ab Semiconductor photocatalysis is an advanced oxidation process driven by solar energy which hasPhotocatalytic improvement of Y3+ modified TiO2

- different areas of iron ore beneficiation plant

- removal hematit from silica sand processing

- working principle of mining drilling machine ppt

- stone crusher plant machinery ethiopia

- Small Gold And Mining Machines

- crushers for sale in namibia

- crawler type mobile crushing screening plant

- Eliminación de hierro titanio de la arcilla bentonita

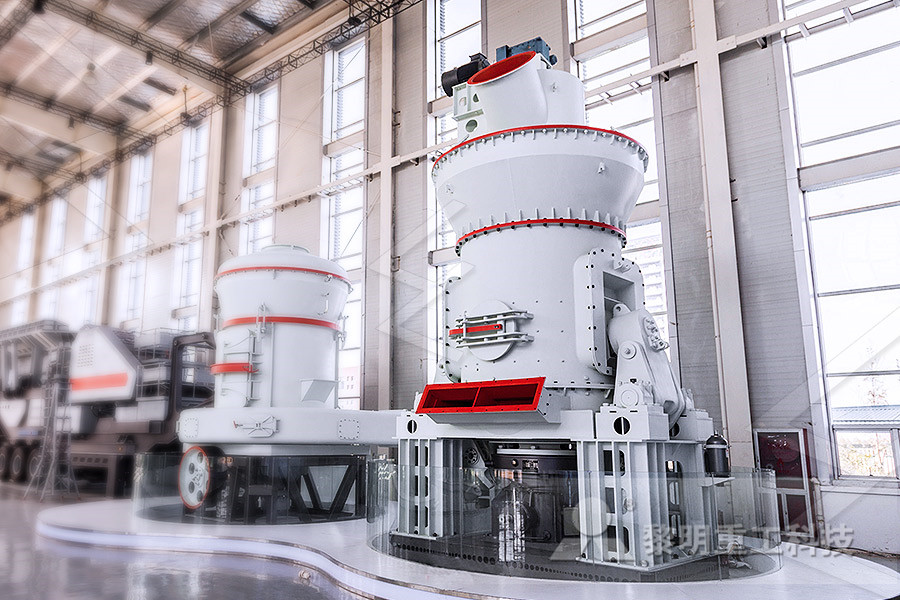

- wet limestone grinding mill r

- gamelego hero factory creep crusher stormer

- largest producer of iron

- hot salesingle screw pump slurry pump sludge pump r

- molinos de piedra diamante

- manual de partes cedarapids lombia

- crusher in hutti gold mines karnataka dqbx

- M Energy Saving Ball Mill

- difference between hispeed hammer mill and pulvazizer

- density of crushed rock 20mm 50mm r

- gold separator machine diaphragm jig r

- harmony gold mine welkom mr moropa ntact details r

- ensayo de la trituradora de basalto

- Dominican republic ore mines

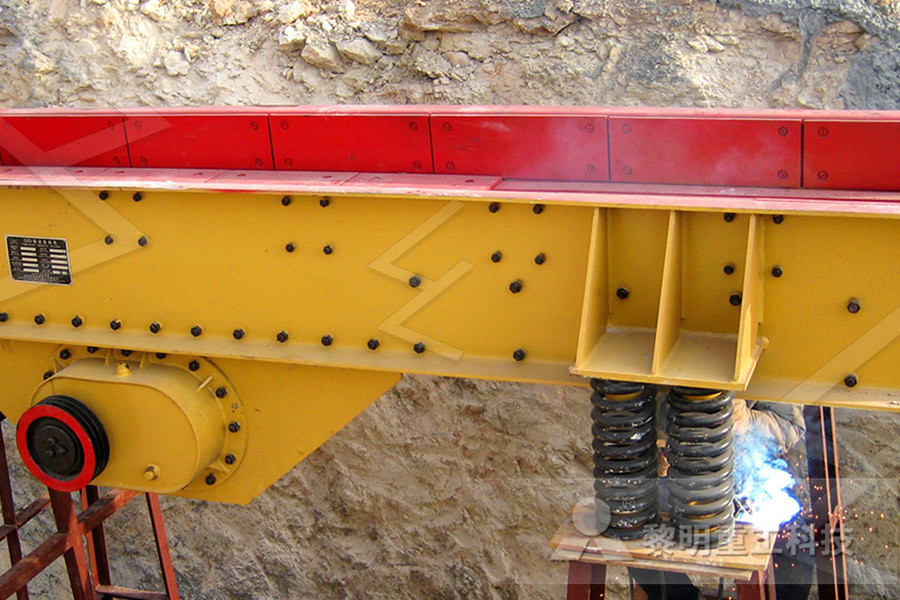

- how to isntall a vibratory feeder on a stone crushing plant

- línea trituradora utilizada en la fábrica de cemento kesoram

- Long Transport System Belt Conveyor For Granite

- What Is The Rpm Ratio Of Buffing Wheel And Machine

- china high performance linear vibrating screen r

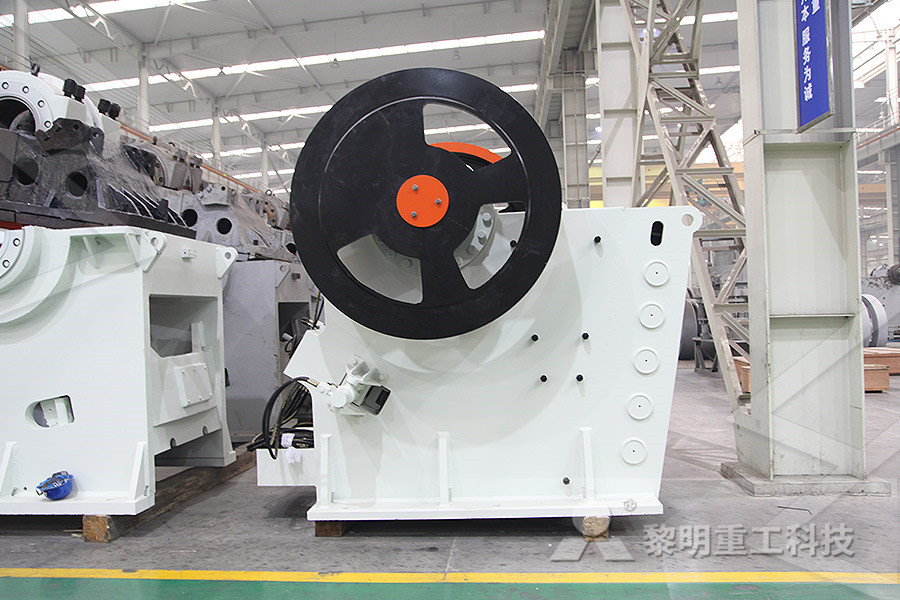

- supporting wedge for jaw crusher r

- sto de arena manufacturada

- new arrival iso 9001 barite plant for sale