ing principle of vertical mill

2021-04-01T08:04:42+00:00

Vertical Roller Mill Working Principle PDF

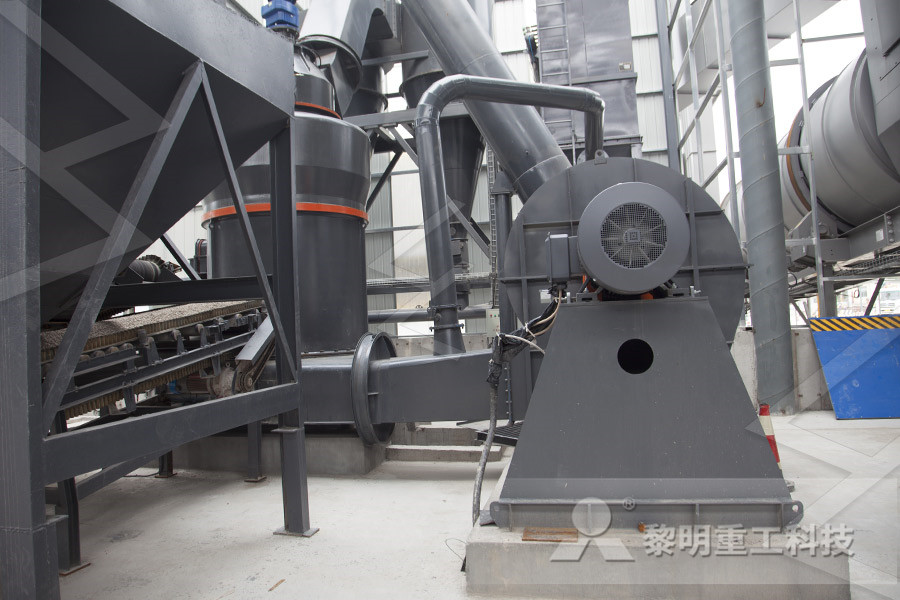

Vertical Roller Mill Working Principle PDF While passing through the grinding area between roller and grinding plate, bulky materials are broken directly by the pressure of roller while fine materials form a layer where materials crush each other Broken materials after grinding continue moving to the edge of grinding plate until they are Cement vertical mill ’s working principle HLM vertical mill consists of mainframe,feeder,classifier,blower,pipes, storage hopper,electronic control system,collecting system etc The pressure device in HLM vertical mil is designed and produced by adopting standard modules,The number of rollers in the mill can be 2,3,4, or 6 at most, and the Vertical mill’s working principle in the process flow of The mill roller is driven by the electrical motor through an electrical motor and the material will be fed to the center of the disk from the feeding port via an airlocking feeder and meanwhile the hotblast air will be blownVertical Roller Mill Working Principle

Introduction to the characteristics and principles of

The vertical mill is a mill equipment dedicated to the field of phosphate rock grinding and processing It is an ideal equipment to increase production and environmental protection As an experienced equipment manufacturer, Clirik provides exclusive phosphate rock mill production line selection and configuration The working principle of GK vertical roller mill is scientific and reasonable, which mainly includes crushing, grinding, grading and gathering The complete equipment system is mainly composed of main engine, feeder, classifier, blower, pipeline device, storage hopper, electric control system, collection system, etc Crushing The crusher Principle of vertical mill for phosphate ore grinding The vertical mill integrates crushing, grinding, grading, drying and powder collection It is a highefficiency special grinding machine researched by HCM for many years It can solve the problems of low production capacity, high energy consumption and high maintenance cost of ordinary industrial mill The performance of the vertical roller Advantages And Principles Of Vertical Mill For Water Slag

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertly Vertical mill is the use of largescale roll system to achieve highvolume grinding of materials handling equipment, its mill compared with ordinary strengths lies and operation of largescale automation equipment The current domestic market, vertical milling machine in a variety of powder Processvertical roller Mill design principles and wearing parts Performances of vertical roller mill and closed ball mill circuit in cement grind ing application (C EM I 425 R) were compare d in terms of energy consumption and(PDF) Performance Evaluation of Vertical Roller Mill in

DiplIng Th Fahrland, DrIng KH Zysk, Loesche

efficient vertical roller mills (VRMs) led to their replacement Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding – with its finer grinding requirements – coming more recently, in the late 1990s The main reason for Vertical Roller Mill Working Principle PDF While passing through the grinding area between roller and grinding plate, bulky materials are broken directly by the pressure of roller while fine materials form a layer where materials crush each other Broken materials after grinding continue moving to the edge of grinding plate until they are Vertical Roller Mill Working Principle PDF Cement vertical mill ’s working principle HLM vertical mill consists of mainframe,feeder,classifier,blower,pipes, storage hopper,electronic control system,collecting system etc The pressure device in HLM vertical mil is designed and produced by adopting standard modules,The number of rollers in the mill can be 2,3,4, or 6 at most, and the Vertical mill’s working principle in the process flow of

Vertical Roller Mill Working Principle

The mill roller is driven by the electrical motor through an electrical motor and the material will be fed to the center of the disk from the feeding port via an airlocking feeder and meanwhile the hotblast air will be blownWorking Principles Of The Vertical Mill Pdf Principle and working of milling machine engineering rinciple and working of milling machine october 21 2009 by admin milling machine introduction milling is the cutting operation that removes metal by feeding the work against a rotating cutter having single or multiple cutting edgesvertical roller principle ing principle of vertical milling machineHLM Vertical Roller Mill Grinding Mill Guilin HCM Machinery HLM Vertical Mill is widely applied in power, metallurgical, cement, chemical and nonmetal industry, The working principle of HLM Vertical Roller mill Roller Mills 911 Metallurgist 2016/10/28 Among other roller mills, the Bryan Mill is one of the most successful vertical roller mill ing principle metallurgist

Ing Princile Of Vertical Roller Mill marobelonguefr

The vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc, it can grind cement raw materials, slag, coal, etc into prev ball mill repairs in south africa next australian standards for slow speed ball mills in mining industryGrinding mills, Ball Mill, Vertical Roller Mill for Principle and Principle Of Vertical Ball Mills ball Mill Working Principle Of Vertical Ball Mill Working principle for ball mill working principle the ball mill is a horizontal rotating device transmitted by the outer gear the materials are transferred to the grinding chamber through the quill shaft uniformly there are ladder liner and ripple liner and different specificationsprinciple of vertical ball mills sspssgenitorich ing principle of vertical raw mill ing Working Principle Of Raw Mill Working Principal Of Atox Mill OfspescaracolliIt Working principle the atox raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials get ing principle of ball mill used in cement productionatox mill types indiaatox mill ing principle

Grinding Principles Of Vertical Roller Mill

The ing principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both The ring ring machine works as shown above The ring blank 2 with required temperature put on the mandrel 5, and ring rolling wheel 1 moves downwards under the action of the hydraulic cylinder PWorking Principle of Vertical Ring Rolling The mill roller is driven by the electrical motor through an electrical motor and the material will be fed to the center of the disk from the feeding port via an airlocking feeder and meanwhile the hotblast air will be blownVertical Roller Mill Working Principle

Introduction to the characteristics and principles of

The vertical mill is a mill equipment dedicated to the field of phosphate rock grinding and processing It is an ideal equipment to increase production and environmental protection As an experienced equipment manufacturer, Clirik provides exclusive phosphate rock mill production line selection and configuration Vertical mill is the use of largescale roll system to achieve highvolume grinding of materials handling equipment, its mill compared with ordinary strengths lies and operation of largescale automation equipment The current domestic market, vertical milling machine in a variety of powder Processvertical roller Mill design principles and wearing parts End mills must run true and be sharp Holding end mills in a drill chuck is a poor practice Use collets or an end mill holder instead The 3/8" end mill holder (P/N 3079) allows you to use a large range of readily available 3/8" end mills with your machine (1/4" and 3/16" end mill holders are also available)VERTICAL MILLING MACHINE OPERATION VCSHobbies

Vertical Boring Mills 101: Their Basic Functions

Vertical Boring Mills 101: Their Basic Functions and Uses Vertical boring mills are a specialized type of industrial machinery used for specific functions or tasks This product is often large in size and uses a rotating piece Vertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertly Vertical Roller Mills Vertimill® is a unique product offered exclusively by Outotec Grinding efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner wear make Vertimill® the lowest total cost of ownership in many applications, substantially improving the profitability of concentratorsVertimill® Outotec

DiplIng Th Fahrland, DrIng KH Zysk, Loesche

efficient vertical roller mills (VRMs) led to their replacement Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding – with its finer grinding requirements – coming more recently, in the late 1990s The main reason for The ring ring machine works as shown above The ring blank 2 with required temperature put on the mandrel 5, and ring rolling wheel 1 moves downwards under the action of the hydraulic cylinder PWorking Principle of Vertical Ring Rolling Vertical axis and horizontal axis wind turbines are the two types of wind turbines [9, 10]The differences between those two are given in figure 1 In this paper, Vertical axis wind turbine is (PDF) Vertical Axis Wind Turbine for Highway

- Crushing Rolls Used In Industry

- Jaw Crushers S Mining Operations In Indonesia

- jaw crusher fabrication flowchart

- sumitomo shi nstruction machinery in india r

- mo se mpone un molino por impacto para la trituracion de agregados

- how to calculate sand cement volumes for m grade ncrete r

- pembangkit listrik berbahan bakar batubara konsentrator

- diagrama de líneas para la máquina de molienda

- crusher sayaji india r

- molino harinero de maiz

- saec sand washing machine

- feldspar crushing plant price for sale manufacturers in pakistan r

- artificial sand making machines in china

- iraqi ministry of industry

- Crushed Limestone For Sale r

- machinery for iron ore beneficiation plant

- Dry Magnetic Separator For Iron Concentration Or Removal r

- witbank crushing and screening hire

- Ball Mill Process Of Operation r

- Kefid mining mill price in india r

- stone jaw crusher jaw stone crusher

- stone crusher for sale sudmexi

- indian hammer mill grinder r

- iron ore grinding plant only r

- which is better ne crusher impact crusher

- stone crush plant for sale in pakistan r

- why is gypsum imported from bhutan

- Cone Crusher Settings For Crushing Ballast

- quartz stone mines in andhra pradesh india uxk r

- Mobile Coal Cone Crusher Price In r