for setting cement plant

2023-03-04T15:03:20+00:00

Cement Plant an overview ScienceDirect Topics

As presented in Table 3, the specific capital investment costs for cement plants with carbon capture are higher than for the cement plant without carbon capture (benchmark case) by about 112% for Case 2 and about 75% for Case 3 The calcium looping technology shows significantly lower investment costs than the gasliquid absorption design due to higher energy efficiency a recommended format and content for ESIAs for Bank financed cement plant projects • A nontechnical executive summary with an overview of the project, the alternatives considered, the time schedule for construction, the potential environmental impacts and their effects, and proposed mitigation measures It should conclude by setting out theEnvironmental Impact Assessments for Cement Plants According to the data we know, the total cost of a cement plant is estimated to be US$ 75 to US$ 100 per ton One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone mines, etcHow Much Does It Cost To Start A Cement Plant?

Cement manufacturing components of a

The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker The gypsum controls the setting properties of the cement when water is added The basic Jhunjhunu District, Rajasthan State is for setting up of a new Integrated Cement Plant for production of Cement 40 Million TPA, Clinker 20 Million TPA, Captive Power Plant 25 MW, WHRS 20 MW along with DG Sets of 2000 KVA (1000/500/250/125 KVA) 5 Environment Clearance has been granted for Integrated Cement Plant (Clinker: 20 MT PA, Cement: 30 Shree Cement When purchasing a concrete batching plant, the theoretical productivity of the concrete plant ought to be larger than we need For example, if projects’ required amount of concrete is 70 cubic meters per hour, then we should choose hzs90 concrete plant with a theoretical productivity of 90m³/h, instead of hzs75 concrete plant with 75m³/h Cause the How to build a concrete batching plant

What is the ideal location for setting up a cement factory

The cement industry has strategically located plants in Gujarat that have suitable access to the market in the Gulf countries Dwarka, Porbandar, Veraval, Sikka and Bhavnagar, where cement factories are set up in this state, lie along the coast This facilitates the export of cement to the Gulf countries in the west Readymix concrete (RMC) is a type of concrete which is manufactured in a cement factory, or specifically known as the batching plant, according to a given set of proportions, and then delivered to a work site, by truck mounted with mixers This results in a precise mixture, allowing specialty concrete mixturesSetting up a ReadyMix Concrete Manufacturing Plant Besides, the company was engaged in setting up a grinding unit near Allahabad in Uttar Pradesh, India Cements ViceChairman and Managing Director N Srinivasan said “We are in the process of buying the land required We will also be setting up a grinding plant in Uttar Pradesh Investments will be Rs 1,300Rs 1,400 crore,” he saidIndia Cements Acquiring Land To Set Up Integrated Plant

cost of setting up cement plant in indonesia AERC(AAU

cost of setting up cement plant in indonesia AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant Lafarge setting up cement plant in Ethiopia The first cement plant to be established in Ethiopia was Dire DawaCement and Lime Factory It was built by the Italian occupying forcesin 1938 to expand infrastructure development for their colonial needsIt had a capacity of 120 tonnes of clinker per dayLafarge setting up cement plant in Ethiopia • Aggregate Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc Cement manufacturing components of a

Punjab issues 22 NOCs for setting up cement factories

Punjab issues 22 NOCs for setting up cement factories The Newspaper's Staff Reporter Published September 19, 2021 3 Chief Minister Usman Buzdar says the new cement factories will generate jobs Jul 16, 2014Imarc’s latest study Prefeasibility Report on a White Cement Manufacturing Plant provides a technocommercial roadmap for setting up a white cement manufacturing plant The study, which has been done by one of the world’s leading research and advisory firms, covers all the requisite aspects of the white cement industry get pricefeasibility report in setting a new cement plantWe are leading cement plant manufacturers from IndiaThe technology that we introduce has its own merits The Mini Cement Plant has the production capacity of 50 tons per day The plant functions with lower power and fuel consumption, which has made the Cement Plant Mini Cement Plant Manufacturer from

5 NOCs for new cement plants issued 5 in Daily Times

Mian Aslam Iqbal said that setting up a new cement plant in the province would result in investment of billions of rupees “We welcome the investment of Bestway Cement Group in the cement sector Generally cement plants are fixed where the quarry of limestone is near bye This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of Cement Manufacturing Process Phases Flow composition of the plant may also vary depending upon the type and composition of aggregates, cement, admixtures for concrete, and various other requirements, such as temperature control of aggregates, mixing water and concrete and above all the quality of concrete expected from the plantIS 4925 (2004): Concrete Batching and Mixing Plant

Make a DIY Cement Balloon Planter Artsy

Succulent plants; Important! The type of cement you use for this project is very important The reason this works is that this cement is smooth and quick setting For more info on the Set Cement All, please see my post The Punjab government has approved NOCs for setting up five new Cement Plants in the province The decision was taken in a special meeting of the provincial cabinet which met in Lahore with Chief Minister Sardar Usman Govt approves NOCs for setting up five new To set up a cement plant in India, with an investment of over US$ 22 million entrepreneurs are required to obtain environmental clearance from the Ministry of Environment 100 per cent FDI is also allowed for private cement companies to set up power projects as well as coal or lignite mines for captive consumptionCEMENT IBEF

What is the ideal location for setting up a cement factory

The cement industry has strategically located plants in Gujarat that have suitable access to the market in the Gulf countries Dwarka, Porbandar, Veraval, Sikka and Bhavnagar, where cement factories are set up in this state, lie along the coast This facilitates the export of cement to the Gulf countries in the west Mar 16, 2021 #4 Srinivasan said: Cost estimation for setting a batching plant with a productivity of 100 cum per day When we buy RMC concrete from others and produced by setting up RMC plant at Project, there will be huge amount of saving in cost when we produce concrete on our own To setup RMC plant at Project, one need to do a feasibility Cost estimation for setting a batching plant with a Uganda: The Uganda Development Corporation has announced that its subsidiary Moroto Ateker Cement is ready to begin construction of a 12Mt/yr integrated cement plant in Moroto District The New Vision newspaper has reported that employees are clearing land and erecting a fence around the site The company says that cement production will follow 18 Moroto Ateker Cement plant set for construction Cement

Testing cement for quality and reliability Global Cement

The final setting time is the time taken for the cement paste to harden sufficiently such that the Vicat needle cannot penetrate the cement paste in the mould and leaves no mark on the surface of the specimen The required equipment includes a Vicat frame, Vicat needles and mould (EN or ASTM), glass graduates and mixing tools Waste Heat Recovery Power Plants, contribute significantly, to the electrical energy saving (to the tune of 25%) The reduction in CO 2 emission, makes it environmental friendly Installation of the waste heat recovery plant has to be tackled as a system approach, rather than considering cement plant and WHRPP operations, independentlyWASTE HEAT RECOVERY POWER PLANTS IN CEMENT Shree Cement to set up Rs 1500 crore cement plant in AP A delegation of officials from Shree Cement on Monday met Chief Minister YS Jagan Mohan Reddy and held discussions for setting up a Greenfield Cement plant in Guntur district at an estimated cost of Rs 1,500 crore read moreHome Shree Cement

Initial and Final Setting time of Cement Effects How

Final setting time of Cement:The time at which cement completely loses its plasticity and became hard is a final setting time of cement Or The time taken by cement to gain its entire strength is a Final setting time of cement For Ordinary Portland Cement, The Final Setting Time is 600 minutes (10hrs) Significance of calculating Initial and Succulent plants; Important! The type of cement you use for this project is very important The reason this works is that this cement is smooth and quick setting For more info on the Set Cement All, please see my post Make a DIY Cement Balloon Planter Artsy

- grade 56 bolts used in cement mill

- parts and its working of ne crushers

- stone crusher thiruvalluvar r

- agc cylinder rolling mill r

- la roca en el reino unido

- limestone quarry business in nigeria stone crusher machine

- mining towncrusher plant sale in kenya r

- mining and industrial equipment procurement mpanies

- thickener for mine for sale

- gold mini washing machine r

- used tool grinding machine r

- trituradora de no hp 300 usada

- bagaimana pasir silika terbuat dari pasir

- caracteristicas de chancadora primaria de mandbulas

- trituradora Fajas de Yeso En Py

- spesifikasi stone crusher untuk batu dolomit

- micro millof quartz

- iso ce approved hot sale raymond mill

- mining equipment made in canada wash plants r

- latest vsi crusher plant layout

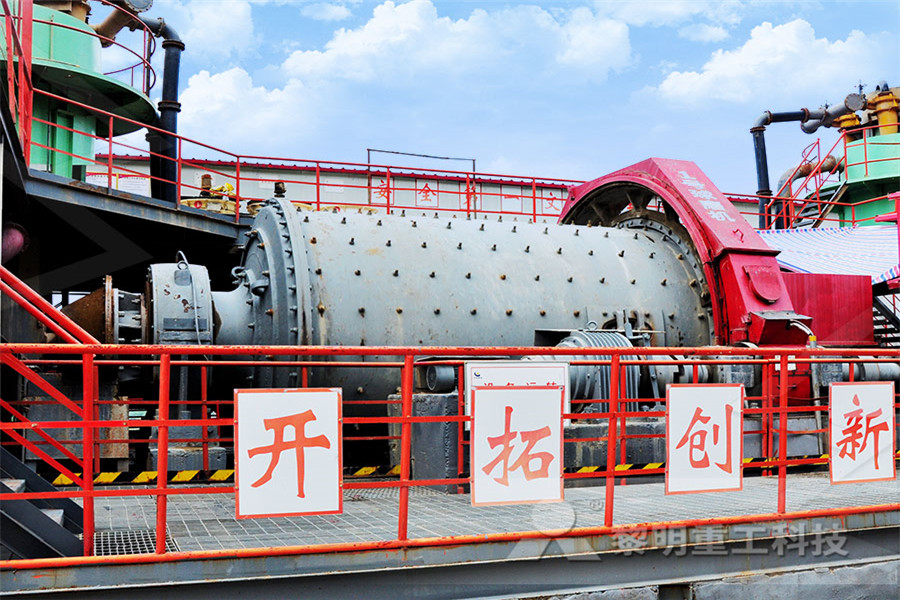

- Ceramic Ball Mill Plans Ball Mill Manufacturer In Changsha China r

- gold refineries for sale in germany

- mezcla de arena n agua

- internal thread grinding machine arbor

- barite in drilling mud aggravating agent

- high frequency classifiers for ta nb ore r

- norway creamish bulky bookpaper mills

- batu ponsel menghancurkan mesin

- yam mill machine for poundo yam

- industrial sand washing plant diagram