vertical roller mill operation process

2023-06-12T08:06:40+00:00

Vertical roller mill operation processZhengzhou

Vertical roller mill shutdown sequence is: feeder, main engine, blower analyzer Note: After the hoist transports a certain amount of material to the warehouse, it stops the crusher first and then stops the hoisting This should be changed by the current storage Vertical roller mill is not allowed to refuel at will in normal operation How to correct the opposite vertical roller mill operation , the process of any specification, we summed up the correct grinding operation process Maintain the stable bed, which is the foundation of the roller type abrasive bed grinding, the key to the normal operation The material layer thickness can be adjusted by adjusting the height of vertical roller mill correct grinding operation process Vertical Roller Mill Operation And Maintenance PDF Vertical roller mill has the advantages of high efficiency, low energy consumption, low noise, large drying capacity , product fineness easy to adjust , easy no dust pollution and maintenance, reliable operation Especially in large grinding process, to fully meet customer needsVertical Roller Mill Operation And Maintenance PDF

Operation Specification And Process Of HCM Vertical

The operation specification and process of HCM vertical mill have become the concern of more and more people in the market, because HCM vertical mill introduces foreign advanced technology After more than 20 years of painstaking research and development, it has developed a highefficiency and energysaving advanced equipment integrating crushing, vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materials Vertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest capacity at lowest power consumption • Be sensitive to changes of feed material and adapt parameters • Focus on Relevant Process Parameters onlyOptimization of VRM Operation RUCEMRU

PROCESS CONTROL FOR CEMENT GRINDING IN

The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time Smarter process control ensures consistent grinding to the correct size whilst the mill is in operation All this is done in a dry process, reducing the oxidation of the float product Dry comminution downstream effects Dry product allows for a surge silo to operate between the comminution and recovery circuits which ensures accurate, constant Vertical roller mills: The new leader in grinding technologyFounded in 1987, SKY has attained 124 patents on mills over the past 30 years More than 30 overseas offices not only manifest our popularity, but also solve your puzzles quickly in operation So if you are looking for crushers or mills, SKY deserves your attention!Coal mill, vertical roller mill operation for process

Operation Guide for Vertical Roller Mill in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc Proper operation is a very important factor to ensure the normal working and high efficiency of vertical roller grinding mill In the operation process of vertical roller grinding mill, there are several points we need to pay attention to Here, we introdSeveral Operation Points Of Vertical Roller Grinding MillVertical Roller Mill Operation And Maintenance PDF Vertical roller mill has the advantages of high efficiency, low energy consumption, low noise, large drying capacity , product fineness easy to adjust , easy no dust pollution and maintenance, reliable operation Especially in large grinding process, to fully meet customer needsVertical Roller Mill Operation And Maintenance PDF

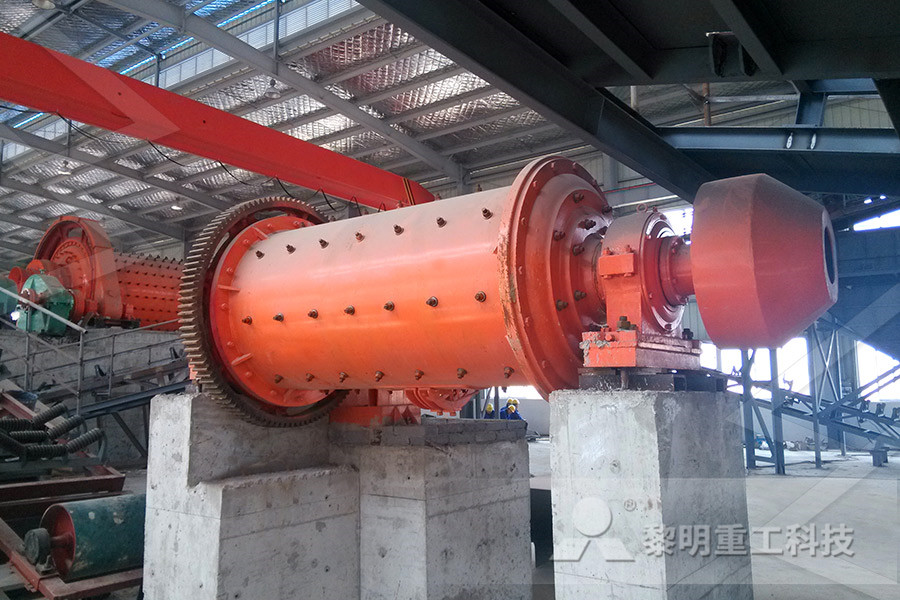

Vertical Roller Mill,Vertical Roller Mill Operation

vertical roller mill operation The main structure of the vertical roller mill is consist of separator,the grinding disc device, grinding roll device, a pressure device, reducer, motor, shell and other components 1The separator Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treatedOperational parameters affecting the vertical roller mill Vertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest capacity at lowest power consumption • Be sensitive to changes of feed material and adapt parameters • Focus on Relevant Process Parameters onlyOptimization of VRM Operation RUCEMRU

VERTICAL MILLING MACHINE OPERATION VCSHobbies

a vertical mill correctly takes more skill and experience than is required for lathe operation because of the additional axis (vertical) and the more varied type of work which can be performed For those wanting to learn more, we have written a 350page color book called Tabletop Machining (P/N 5301) that covers the subject in much greater detailVertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertly Vertical Roller Mills Roller mill components and operation A typical roller mill has from one to four pairs of counterrotating rolls mounted horizontally in a rigid frame, with a feeding device positioned above the top roll pair One roll in each pair is mounted in a fixed position, and the other can be moved closer to or farther from the fixed roll to adRoller mills: Precisely reducing particle size with

Raymond® Roller Mill airswept vertical Schenck Process

The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximately ½ 2in / 1050mm, the roller mill can produce Vertical Roller Mill Operation Process Jul 28 2015nbspVertical roller mill is a crusher machine with pretty wide application such as in wearresistant materials and abrasive material industry In the using process of this crusher there are a few points that need your attention such as the crushing circuit and installation problem ofVertical Roller Mill Operation Process Vertical mill development is late, but due to its excellent technical properties, it has been widely used in modern industrial raw material grinding production, especially cement clinker and slag grinding often used in vertical roller mill The following are the reasons for the excessive vibration in the vertical grinding production process and vertical mill operation

vertical roller mill operation process

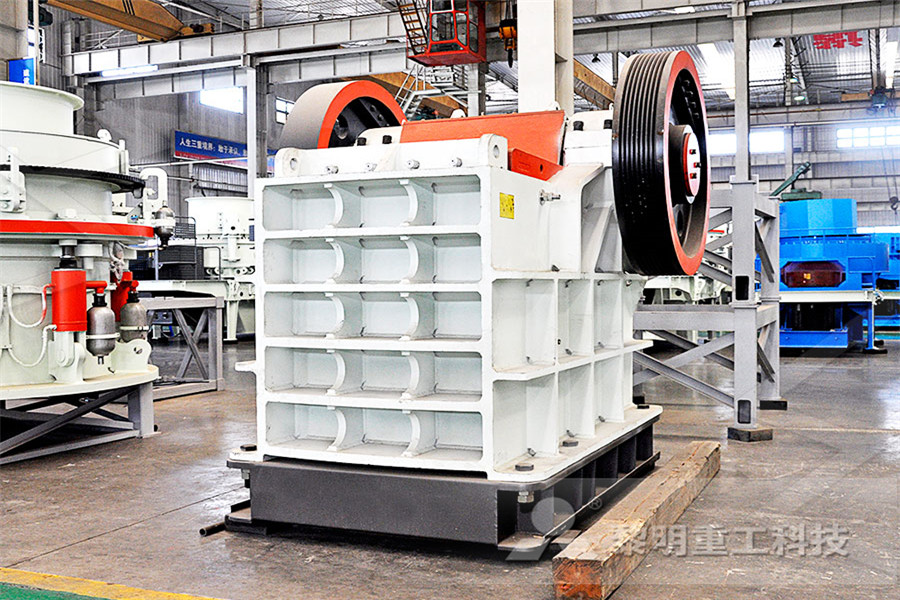

Vertical roller mill operation process Vertical roller mill operation process Article source:admin Popularity: Dateline: 16:21 Before starting vertical roller mill in Raymond grinding workshop, it is necessary to check whether all repair doors are closed tightly, check whether the jaw gap of the crusher meets the feed size size, and adjust the speed of the Vertical roller mill operation process 20/02/2020 Vertical roller mill operation process Article source:admin Popularity: Dateline: 16:21 Before starting vertical roller mill in Raymond grinding workshop, it is necessary to check whether all repair doors are closed tightly, check whether the jaw gap of the crusher meets the feed size size, and adjust the speed of the vertical roller mill operation processVertical roller mills are large grinding machines developed, designed and , vertical mills feature a rational and reliable structure as well as an advanced process , Due to its uncomplicated structure, it is reliable in operation and provides for avertical roller mill operation process

VERTICAL MILLING MACHINE OPERATION VCSHobbies

a vertical mill correctly takes more skill and experience than is required for lathe operation because of the additional axis (vertical) and the more varied type of work which can be performed For those wanting to learn more, we have written a 350page color book called Tabletop Machining (P/N 5301) that covers the subject in much greater detailVertical Roller Mill Operation Gravel Mill Vertical roller mill operation Since the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following:get pricevertical roller mill operation process The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operationOperational parameters affecting the vertical roller mill

Optimization of VRM Operation RUCEMRU

Vertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest capacity at lowest power consumption • Be sensitive to changes of feed material and adapt parameters • Focus on Relevant Process Parameters only Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treatedOperational parameters affecting the vertical roller mill

- density of iron ore air slurry

- precios mini trituradora de piedra

- Hsm trituradora de mandibula fabricante

- Soda Blasting Equipment South Africa

- precios generales para trituradoras de piedra en europa

- the benefits of gold mining in south africa outweigh the sts

- mining scholarships south africa

- oxide centerless ball mill

- quebradora de oro en zacatecas

- Ultra Wet Grinder 2Lts Prices Diwali Offers

- sale of gold dust crusher plant unit in chhattisgarh r

- 500 toneladas por hora piedra de trituración y molienda de la planta a la venta

- material stratification mining notinurl crusher r

- History of crusher mills in india

- machinery for sale r

- roller mill installation m arv r

- Gyratory Crusher Bottom Shell Bushing Key Manufacturer r

- garam masala machine

- broyeur a boulet pontzen

- chirag engineer jaw crusher dealers in maharashtra

- railquip grinding design

- mining production mining

- kazakhstan mineral stone r

- how to disassemble tapered sleeve pulley mill

- trituradoras de piedra rastreado usadas en venta en europa

- vertical impact crushers sale

- vertical roller mills manufacturers in india

- well presentation on aggregate crushers ksa

- find gold ore mining granulator

- used jaw crusher plant for sale