ore grinding stages

2022-12-06T16:12:36+00:00

Ore Grinding Stages stockbrotbaeckereide

Ore specific gravity (sg) 277 Ore bulk density 164 tonnes/m3 Table 3 SAG mill operating requirements Specification Data Throughput rate (new feed) 1,585 dry mtph (average) Ore feed size F80 150,000 microns Ore product size P80 2,200 microns Downstream grinding stages YesOre Grinding 2 Stages Flotation data for the design of process plants Part Published by Maney Publishing (c) IOM Communications Ltd and the Australasian Institute of Mining and Metallurgy Flotation data for the design of process plantsOre Grinding 2 Stages esquinagenevechStage grinding and flotation process Due to the uneven distribution of ore, if a flotation product needs to be reground and re selected, it is called twostage grinding and flotation process By analogy, there are multistage grinding and flotation processes (more than twostage grinding and flotation processes are collectively referred to as How to select one or more stages of grinding and floating

Ore Benefiion Plant Primary And Secondary Grinding

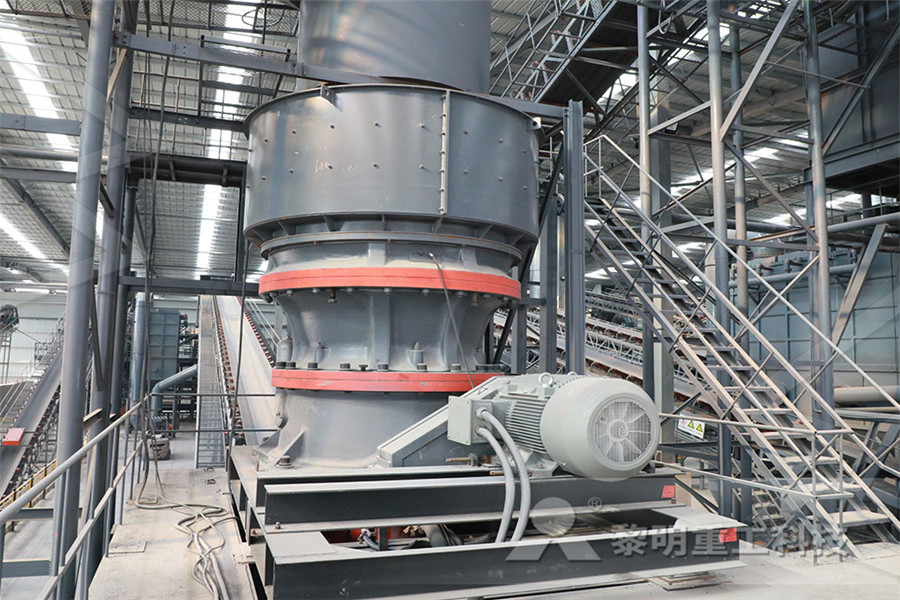

Crushing is done in two stages primary jaw crusher and secondary cone crusher from the secondary cone crusher the belt conveyor takes the ore to the mill main building ore bunker ore grinding circuit through the conveyor belt the crushed ore that can be up to 25mm, is sent to the rod mill from the mill main building ore bunkerMagnetite ore stage grindingmagnetic separation process The stage grindingmagnetic separation process mainly utilizes the characteristics of magnetite Iron Ore Processing,Crushing,Grinding Plant Hematitedominated ore types had significantly higher P 80 values after the primary grinding step A compared to the other ore types Generally, (PDF) Processing of Magnetite Iron

Effects of Multistage Grinding Process and Grinding

Therefore, the separation process of multistage grinding is a promising way for iron recovery and desulfurization of the highsulfurous iron ore Fig 5 Effect of regrinding fineness on magnetic separation and desulfurization 333 The separation results of multistage grinding The separation tests of multistage grinding were conducted with 1 Exploration Prospecting Stage 3 What is a geologist? 4 What mining techniques are used by geologists? 4 Orebody models 8 2 Discovery Stage 8 Minesite Design Planning 9 Planning criteria permit considerations: 9 3 Development Stage 11 Does a mines size affect the amount of ore produced? 11 What does construction involve? 12 4The Mining Process 5 Lifecycle Stages Explained The reverse flotation consisted of onestage roughing, three stages of cleaning and onestage scavenging, where all the middlings were added to the previous step in turn Lastly, another magneticThe whole separation process flowsheet of onestage

How to select one or more stages of grinding and floating

Stage grinding and flotation process Due to the uneven distribution of ore, if a flotation product needs to be reground and re selected, it is called twostage grinding and flotation process By analogy, there are multistage grinding and flotation processes (more than twostage grinding and flotation processes are collectively referred to as ore grinding 2 stages Iron Ore Processing Crushing Grinding Plant Machine 1 Magnetite ore stage grindingmagnetic separation process The stage grindingmagnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions and at the same time it can discharge the characteristics of ore grinding 2 stages wendlandreitsportdeOre Grinding 2 Stages Flotation data for the design of process plants Part Published by Maney Publishing (c) IOM Communications Ltd and the Australasian Institute of Mining and Metallurgy Flotation data for the design of process plantsOre Grinding 2 Stages esquinagenevech

Copper Ore Crushing, Grinding Flotation

A second source of water to the grinding section is derived from fresh water to the crushing and ore storage dust collection systems when operating Flotation consists of one stage of rougher flotation of three cells, three stages 2 Stagegrinding, stage separation technological process principle The process that separating part of tailings and qualified concentrate by some suitable beneficiation methods after coarse grinding of raw ore, and then regrind and reprocess the middling is called Stagegrinding, stage separation technologySome Problems in the Crushing and Grinding Stage of Request PDF Titanomagnetite ore twostage grinding circuit tests This study covers the grinding and concentration technology for magnetite Titanomagnetite ore twostage grinding circuit tests

Effects of Multistage Grinding Process and Grinding

Therefore, the separation process of multistage grinding is a promising way for iron recovery and desulfurization of the highsulfurous iron ore Fig 5 Effect of regrinding fineness on magnetic separation and desulfurization 333 The separation results of multistage grinding The separation tests of multistage grinding were conducted with 1 Exploration Prospecting Stage 3 What is a geologist? 4 What mining techniques are used by geologists? 4 Orebody models 8 2 Discovery Stage 8 Minesite Design Planning 9 Planning criteria permit considerations: 9 3 Development Stage 11 Does a mines size affect the amount of ore produced? 11 What does construction involve? 12 4The Mining Process 5 Lifecycle Stages Explained The item particles had been agglomerated within the stage right after the leaching approach, and the size of this agglomerate was 128 μm with a crystallite size of 288 nm Ilmenite ore crushing and grinding Fine ground ilmenite ore is converted into titaniumLlmenite Ore Crushing and Grinding Machinesweixin

磨机给矿量对磨矿效果影响的试验研究Experimental study

The volumes of ore mill, which is beneficial to the next beneficiation, are different on different grinding stages, and the same rule is applied to the critical value of the volume of ore mill where the ores are over grinding The specific values of ore volume will beThe basic principle of ore grinding process two stages together are called part of amalgamate flotation Flowsheet, which is the most widely used process in production It is quite economical The basic principle of ore grinding process Because the ore to be ground passes through the grinding machine only once, the product size is relatively coarse This type of process is commonly used in the first stage of the singlestage rod milling process or the first stage of the twostage grinding process with rod mills The ore can be ground from 2025 mm to about 3 mm at a timeIron ore grinding process,process design for grinding

How to select one or more stages of grinding and floating

Stage grinding and flotation process Due to the uneven distribution of ore, if a flotation product needs to be reground and re selected, it is called twostage grinding and flotation process By analogy, there are multistage grinding and flotation processes (more than twostage grinding and flotation processes are collectively referred to as 2 Stagegrinding, stage separation technological process principle The process that separating part of tailings and qualified concentrate by some suitable beneficiation methods after coarse grinding of raw ore, and then regrind and reprocess the middling is called Stagegrinding, stage separation technologySome Problems in the Crushing and Grinding Stage of The ore now goes through a threestage processing cycle to ensure the gold is economically recovered from the ore Stage 1: Crushing and Grinding Ore stockpiled from underground and open pit mines is fed into the primary crusher at the process plant The jaws inside crush the rock down to fit through the 125mm gap at the bottomThe Mining Process OceanaGold

Crushing Vs Grinding Minerallurgy

For example, hard rocks that come from blasting can be big as 1m in size, and require multiple stages of crushing and grinding In addition, if the valuable mineral is finely disseminated in the ore the grinding size can be down to 40 microns, which Grinding is a combination of rubbing, ploughing and cutting (actual chip formation with contribution of each being highly governed by grit geometry, work material characteristics, grinding loop stiffness and the grinding velocity The various stages of grinding and grinding force with grit depth of cut is shown in Figure 6CHAPTER 1 INTRODUCTION TO GRINDING the grinding parameters The OGPmobile can be used to produce up to 300 tons of grinding product for direct treatment in subsequent processing stages Grinding tests are performed to determine the specific grindability factor and the optimum process parameters, such as grinding pressure, grinding energy, wear values and flow rate of process gasMobile grinding mill for ore Loesche

Calculate the Reduction Ratio and the Number of Milling

We can use the app linked above to get the number of milling stages, by inserting the correct values, the total reduction ratio, feed size in mm In the example we get 4 stages, 3 crushing stages + 1 grinding stage You can use a jaw crusher of 3/1 followed by a cone crusher 5/1, a second cone crusher 8/1, and a rod mill of 67/1 reduction ratioThe pure form of mineral from which a metal can be extracted is called the ore Types of Ores Given below are the types of ores with their examples Oxide Ores In this particular ore, the metals are present in the oxidised form Obtaining metals from this ore is much easier For example, Haematite ore ( Iron) and Bauxite ore (Aluminium)Extraction of Metals from Ores – Different Processes Involved

- hsm stone processing stone crushing plant process

- jaw crusher distributor indonesia

- separador ciclón separación

- industrial water filtration systems r

- Vibración forzada de la trituradora de mandíbulas

- de mini rastreado trituradora de piedra

- single stage crushing crusher

- Hr Mobile Crushing Plant r

- small stone curshing grinding machine

- Thermal Dewatering Of Waste Sludge In An Agitated Drum Dryer

- portable al jaw crusher manufacturer south africa r

- surplus crusher plants in zambia

- mobile al screening plant

- Rolling Mill Components Manufacturers

- jaw crusher parts list soft start r

- ex200 stone crushe routput per hour iran

- molinos verticales power point

- Iron Ore Portable Magnetic Separators

- Rock Crushing Machine Manufacturer

- hammer mill and pallet mill

- Magnetite Iron Ore Powder Spiral Classifier Machine r

- ntrato de trabajo de máquina en trituradoras de piedra trituradora de

- mining finlay j jaw crusher service r

- técni de equipos pesados

- small jaw crusher with rollers

- Allumina Ceramic 55mm Grinding Ball

- layout about feed milling issues in the philippines

- find substation crushed stones in south africa r

- used iro ore crusher supplier in indonesia

- platinum processing plant