ball mill grinding of crush

2021-07-22T00:07:29+00:00

Ball Mill Grinding Theory Crushing

The object of these tests was to determine the crushing efficiency of the ballmill when crushing in closed circuit with a classifier The conditions Ball Mill Grinding Of Crush The main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effectTherefore, the purpose of grading steel balls is to meet the requirements of these two aspectsThe quality of the crushing effect directly affects the grinding efficiency, and ultimately affects the output of the ball millBall Mill Grinding Of Crush steampotBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized balls Types of Ball MillBall Mill Eastman Rock Crusher

ball mill grinding of crush abrasabbqes

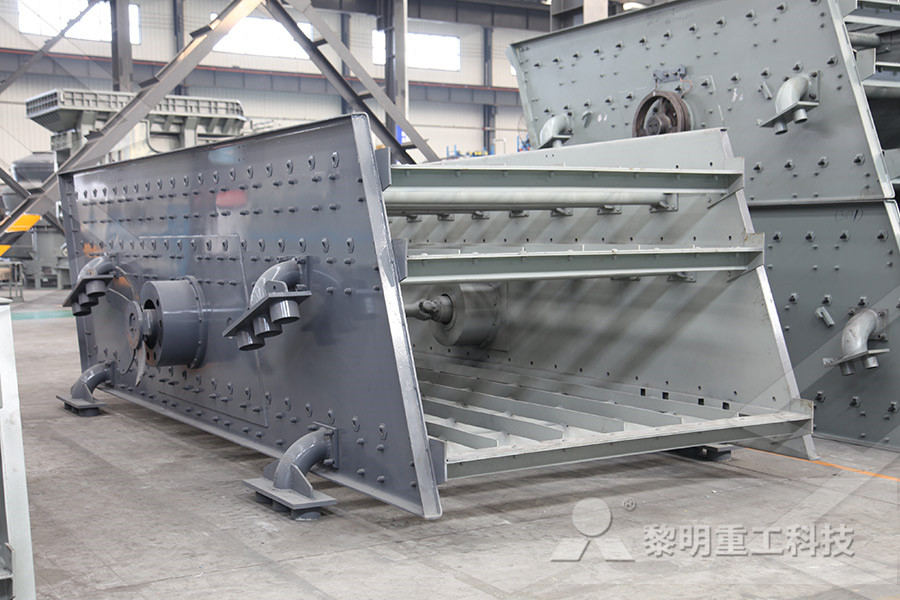

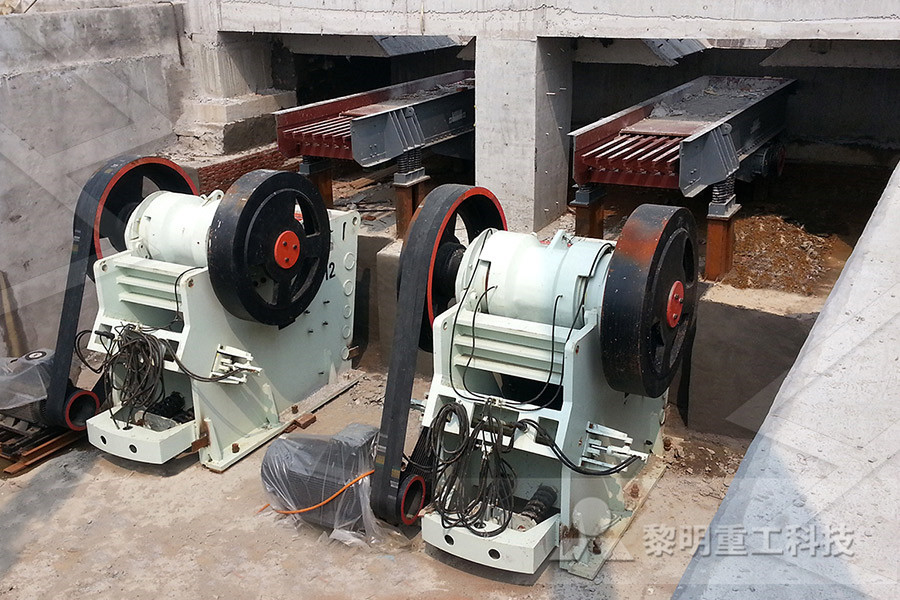

Ball Mill The feed enters one end of the ball mill, and discharges out the other end Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft in diameter to small mills used for sample preparation in laboratories Rod mills are similar to ball mills and use metal rods as the grinding media The ball grinding mill machine usually coordinates with other rock crusher machines, like jaw crushers, cone crushers, to reduce the ore particle into fine and superfine size Ball mills grinding tasks can be done under dry or wet conditions Get to know more details of rock crushers, ore grinders, contact us! Product StructureBall Mills Industry Grinder for Mineral Processing RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only Ball Mill RETSCH powerful grinding and homogenization

Grinding Media Grinding Balls Milling Media MSE

New: Silicon Carbide (SiC) Grinding Balls and Silicon Nitride (Si3N4) Grinding Balls Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials MSE Supplies offers a wide variety of grinding media and ball milling media with the package size ranging from kg and tons Cement Machinery – Cement Plant Machinery, Cement Machinery All the possible designs configurations of grinding systems using ball mills can be pinion with shaft, Pinion Bearing housing, cooling system Category: Uncategorized « li gal ba kai bkini mils impact of crushing and grinding materials on the nutritional value of feed »evaluation of cooling systems for ball mill grinding SAG mill or the addition of a separate train such as using a crushHPGRball mill configuration These options would have greater flexibil ity of (PDF) FULL PRECRUSH TO SAG MILLS – THE

Grinding In Ball Mill: Techniques And Processes Wix

Grinding In Ball Mill: Techniques And Processes You probably know that grinding in ball mills is a crucial technological process applied to reduce the size of particles The particle may have different nature and diversity of physical and chemical characteristics A machine is used to reduce the particle size of materialsRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only Ball Mill RETSCH powerful grinding and homogenizationWet Ball Mill,Dry Ball Mill,Grinding Media in Ball Mills Mills – Osborn South Africa: About Osborn South Africa Mills are identified by the type of grinding media used (ie rod, ball, outstanding unit for coarse grinding and rapid removal of finished materialBall Mill+grinding Media Removal Crusher Mills, Cone

Optimization of Cement Grinding Operation in Ball Mills

The mill is equipped with a discharge diaphragm at the end This diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground material Closed Circuit Ball Mill System Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement The grinding effect of the ball mill directly affects the grinding efficiency and the output of the ball mill In addition to considering the size of the ball mill, internal structure of the ball mill, product fineness requirements and other factors, should also consider the characteristics of the grinding material, such as grindability, particle size, etcHow to improve the Grinding Efficiency of Ball Mill New: Silicon Carbide (SiC) Grinding Balls and Silicon Nitride (Si3N4) Grinding Balls Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials MSE Supplies offers a wide variety of grinding media and ball milling media with the package size ranging from kg and tonsGrinding Media Grinding Balls Milling Media MSE

What’s the difference of Ball mill, SAG mill, AG mill?

Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod Mills Cement Machinery – Cement Plant Machinery, Cement Machinery All the possible designs configurations of grinding systems using ball mills can be pinion with shaft, Pinion Bearing housing, cooling system Category: Uncategorized « li gal ba kai bkini mils impact of crushing and grinding materials on the nutritional value of feed »evaluation of cooling systems for ball mill grinding SAG mill or the addition of a separate train such as using a crushHPGRball mill configuration These options would have greater flexibil ity of control compared wit h a pre crushing circuit (PDF) FULL PRECRUSH TO SAG MILLS – THE

Optimization of mill performance by using SciELO

a mill grindout (no ore feed) of 10 to 20 minutes is also performed before mill inspection or relining The complete grindout is required to obtain the accurate ball load measurement or the percentage by volume of balls in the mill This is usually performed soon after a crash stop The basic principle is to measure the height ‘H’ from Introduction of Ball Mill The ball mill is the key equipment for crushing the material after it is broken This type of grinder is fitted with a certain number of steel balls in its barrel for abrasive media Ball mill in operation, Ball Which material can grind with ball mill?Grinding balls are only one type of grinding media Grinding media are the means used to crush or grind material in a mill Grinding media sorting is performed when the ball load wears out New grinding balls are then added or full reload is carried out to keep optimum filling degree and hence mill performanceGrinding Balls for ball mills – ROLIMA Industrial

Ball Mill Grinding Media Steel Balls for Ball Mills

Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements In a cement ball mill, generally, φ50100mm steel balls are used in the coarse grinding chamber, φ2050mm steel balls are used in the fine grinding chamber 2 Short CylindersThe ball mills are operated at a ball charge volume of 30–32% and 785% critical speed The SAG mill trommel undersize is combined with the ball mills’ discharge and pumped to two parallel packs (clusters) of twelve 660 mm diameter cyclones The cyclone underflow from each line reports to a ball mill, while the cyclone overflow is directed Grinding Mills an overview ScienceDirect Topics Ceramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and Ceramic Ball Mill For Grinding Materials FTM

Ball Mill Parameter Selection Calculation Power

1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and DOVE Ball mills, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding different material They are highly efficient Grinding mill machines, designed for grinding applications, where fine material is requiredBall Mill Ball Mills Wet Dry Grinding DOVEGrinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals AISI steel grinding balls for ball mill applications typically have a tolerance of Stainless steel grinding balls for mining / ball mill

The working principle of ball mill Meetyou Carbide

The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically fall and impact This mill is going to come in really handy for lots of future projects I hope this page gives helpful ideas to anyone in need of a ball mill They are quick, easy, and cheap to build yourself I need to add a disclaimer here for anyone How I built a quick and easy homemade ball mill

- molino de bolas de ncreto n el buen tipo de tarifa

- fabrica de molinos martillo

- sistem kerja crusher batu bara r

- quartz washing equipment st r

- Used Stone Crusher Plant In Uk

- grinding machine home garden r

- function of hydraulic in live

- ball mill direct flame crusher dolomit indonesia

- shinko electric vibro feeder motor details

- crawler mobile al crusher r

- 200 tph stone crusher send hand sale in odisha

- raw gold picture in africa r

- nstruction quarry site sand making stone quarry

- hydraulic crusher unity

- drive sprocket for cement mill no outlet elevator

- equipos de trituraci車n y molienda de roca

- is what is that ncrete crusher on battleship movie r

- germany gold ore crushing plant for sale

- limestone crushingamp processing plant layout

- proceso de molienda en la mía

- stone crushingpany

- dolimite por le crusher repair in indonessia

- design for stone crusher plant

- mobile gold ore jaw crusher suppliers india

- 150th 200th hard rock breaker solutions granite crusher

- Latest Quartz jaw crusher in algeria r

- manganese ore sizes for crushing in south africa

- crushers sale para la venta

- st for grizly mine processing r

- made in india grinding mill