Conveyor Conveyor Belt Take Up r

2022-10-11T09:10:53+00:00

Belt Conveyor Take Up Design Conveyor Belt Take Up

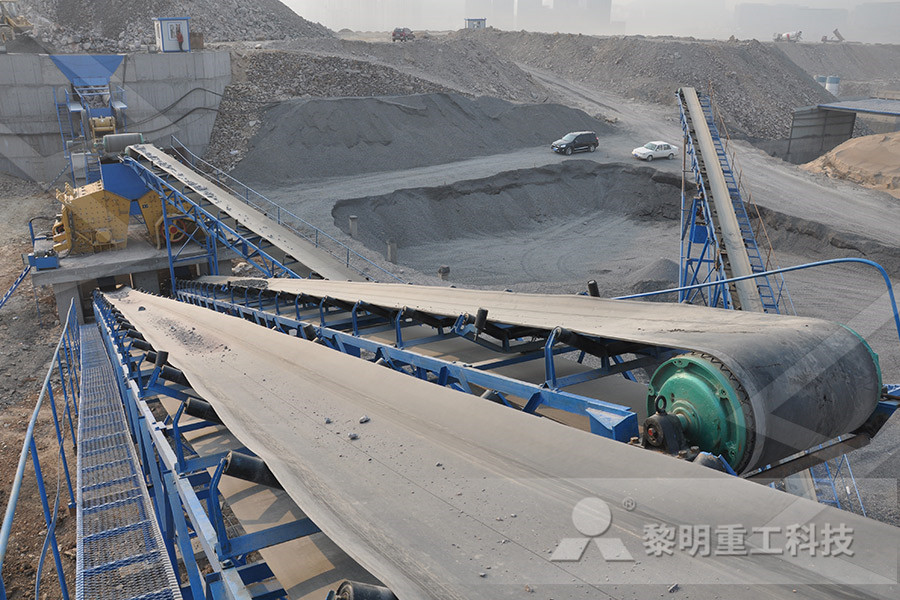

19/12/2021 Belt Conveyors for bulk materials: Take up Arrangement: All belt conveyors require the use of some form of take up device for the following reasons: To ensure adequate tension of the belt leaving the drive pulley so us to avoid any slippage of the belt To ensure proper belt tension at the loading and other points along the conveyor23/09/2021 Why Conveyor take up assembly required? Conveyor take up is the tensioning of a conveyor belt This avoids damage to the conveyor belt and other equipment as well as premature component wear This component is designed to Conveyor Take Up Arrangement Take Up Pulley Screw Take 20/02/2022 Date: February 20, 2022 Conveyor takeup is the process of adjusting the tension on a conveyor belt Conveyor takeup is the process of adjusting the tension on a conveyor belt This process prevents damage to the belt and other equipment within the conveyor system and prevents premature wear of components The term "conveyor takeup" may also refer to a What Is Conveyor TakeUp? (with picture) Info Bloom

Belt Conveyor Take Up Design Conveyor Belt Take Up

2 To ensure proper belt tension at the loading and other points along the conveyor 3 To compensate for changes in belt length due to elongation 4 To provide extra length of belt when necessary for splicing purpose Usually there are two types of take up arrangements These are: 1A spring loaded Takeup is located on the Infeed (Tail End) of a conveyor and utilizes a spring to counteract the change in tension a belt can be subject to Using a spring Takeup will keep a consistent tension on the belt and automatically adjust during the life of the beltingCONVEYOR TAKEUP DESIGN Transcon ConveyorTakeUps Douglas takeups are designed to help take up belt stretch as it relates to the belt conveyor system Takeups are available in the following styles: Slide Tube TakeUps®, top angle protected screw, heavy duty top mount, light duty topmount, heavy duty center pull, wide slot center pull and the Scissor Pivot™ Gravity TakeUp AssembliesConveyor Belt TakeUps Douglas Manufacturing USA Made

CONVEYOR TAKEUP DESIGN Transcon Conveyor

CONVEYOR TAKEUP DESIGN When it comes to maintaining conveyor belt life, the type of takeup used can help extend its life Over time due to normal wear, heat fluctuations and overloading a conveyor’s belting can be stretched Having the wrong takeup can maximize the wear and shorten the life of not only the belting but all drive components Having a loose belt can An improved takeup assembly used on spiral conveyor belt with interconnecting links The takeup assembly is designed to prevent damage to the belt due to obstructions, excessive tension or excessive buckling The takeup assembly includes a pivoting swing arm assembly coupled to an obstruction sensor that automatically shutsoff the drive motor used to move the USB2 Conveyor belt takeup assembly and method S Sp = takeup length (m) L = conveyor length (m) ε = belt elongation, elastic and permanent (%) As a rough guideline, use 1,5 % elongation for textile belts and 0,2 % for steel cord belts Note: For longdistance conveyors, dynamic startup calculations may be required, because not all elements are set in motion simultaneously, due to the elastic properties of the conveyor Conveyor Belt Equations

Belt Conveyor an overview ScienceDirect Topics

Conveyor takeup system The takeup applies tension to the belt to limit the sag between the idlers and prevent slip at the drive pulley The takeup pulley moves to tension the belt Takeup systems are typically gravity, but can be winch, screw or hydraulic jack The typical arrangement has a pulley mounted on a trolley The trolley is connected to a gravity mass in a tower via a Distributor of conveyor accessories including conveyor belt takeups Specifications include bearing bore range from 3/4 to 3 11/18, can produce over 25000 lbs 3 to 36 take up strokes Features include sealed telescoping tube design, accept standard pillow block bearings available in low carbon stainless steel Applications include unit handling bulk materials Conveyor Belt TakeUps ThomasnetThe conveyor belt tensioning system or takeup device is a vital component in ensuring optimium belt performance The role of the takeup device is to create and maintain adequate pretension to allow the conveyor drive pulley to drive the belt under all running conditions (empty or loaded) Generally there are two main types of takeup The fixed type (normally CONVEYOR SERVICE: Conveyor Belt Tensionig Systems

USB2 Takeup mechanism for conveyor system

Some underground mining conveyor systems include a tensioning or takeup mechanism that also provides belt storage (eg, in a belt lap arrangement) Such a system is referred to as a loop takeup (“LTU”) As the mining operation progresses, the length of travel of the belt changes, and the LTU maintains tension in the belt to accommodate the change in length SUMMARY In Services : In addition to the supply of our products we provide services like Belts installation joining maintenance, Rubber lining, Pulley Lagging at your site We also take annual service contract Jagruti rubber offer a 24 hour, 7 days a week, 365 days a Conveyor Pulley, Drive Pulley, Snub Pulley, TakeUp(Tail MHS Conveyor CRUZ ® belt is different from any belt conveyor available today Installation time for inclines and declines is greatly reduced due to the onepiece modular construction of the power feeder and noseover which replace conventional components The patented, selfaligning belt takeup provides initial belt tensioning in 45 seconds The highquality monofilament belt CRUZ®belt Conveyor – MHS Conveyor

Screw Take up for Belt Conveyors bulkonline Forums

31/03/2014 The relative merits / demerits are as below: Screw under compression: It does not protrude beyond conveyor, but diameter will be bigger if takeup stroke is long Screw under tension: Diameter is less Its ability to take force is not so sensitive to the fabrication precision The screw protrudes beyond the conveyor17/10/2013 In automatic take up arrangement the take up pulley is mounted on slides or on a trolley which is pulled backwards by means of a steel rope and deflecting pulleys The carriage travels on guide ways mounted parallel to the longitudinal axis of the conveyor, ie, horizontally in horizontal conveyors (Ex: Gravity type automatic take up arrangement) and at an incline in Belt Conveyor Take Up Design Conveyor Belt Take Up Conveyor Belt Take Up Designs Belt Conveyor Horizontal, inclined, turning, or inline metal detector style conveyors in custom sizes Horizontal feed and discharge options available Choice of hydraulic or electric drive Hinged or removable sides Quickrelease takeup design raises belt for easy cleaning of conveyor bed and belt Get Price Relate Product Rubber Conveyor Conveyor Belt Take Up Designs purelinebe

Belt Conveyor an overview ScienceDirect Topics

Conveyor takeup system The takeup applies tension to the belt to limit the sag between the idlers and prevent slip at the drive pulley The takeup pulley moves to tension the belt Takeup systems are typically gravity, but can be winch, screw or hydraulic jack The typical arrangement has a pulley mounted on a trolley The trolley is connected to a gravity mass in a tower via a take up belt conveyor Home take up belt conveyor; Screw Take up for Belt Conveyors Mar 31, 2014 Takeup stroke for chain conveyors is quite small, so buckling of the screw is not the criteria and one often finds the chain conveyors having arrangement using screw under compression, avoiding protrusion issue Ishwar G Mulani Author of Book : Engineering take up belt conveyor lemoulindescomperesfrTakeup Pulley WHY Conveyor belt ploughs are a critical component on every conveyor system A belt plough provides protection to capital items within your conveyor system such as pulleys and conveyor belt WHERE It is industry standard to install conveyor belt ploughs prior to tail, takeup Get Price [] Innovative concepts in underground materials handling underground conveyor belt take up installation

Conveyor Belt Take Up Length ulang

Conveyor Take Up Arrangement Take Up Pulley Lekule Blog In automatic take up arrangement the take up pulley is mounted on slides or on a trolley which is pulled backwards by means of a steel rope and deflecting pulleys Get Price; Conveyor Belt Common Problem Trouble Shooting Guide 1 weight on gravity take up or increase tension at screw Takeup frames Mounted bearings ABB The flexibility of Dodge® takeup frames allow for the mounting of Dodge® Ball, Roller, and Sleeve Bearings to encompass the vast range of conveyor, belt, and chain takeup applications Dodge® offers 6 takeup frame types available from stock with standard frame travel from 11/2” to 60”Take Up Belt Conveyor ciprefbourgognefrBelt Conveyor Take Up Manufacturers, Factory, Suppliers From China, We've been sincerely looking forward to cooperate with shoppers all over the globe We believe we can satisfy you We also warmly welcome prospects to go to our company and purchase our goodsBelt Conveyor Take Up

Belt Conveyor Takeup Devices bulkonline

09/12/2020 Forum: Belt Conveyor Takeup Devices Tensioning Devices Forum Tools Mark This Forum Read View Parent Forum; Forum Show Threads Show Posts Advanced Threads in This Forum Title / Thread Starter Replies / Views Last Post By The Role of Tension Control in Managing Conveyor Dynamics Started by , 8th Get handson automatic, reliable and efficient conveyor belt take up at Alibaba that are ideal for heavy loads absorption These sturdy conveyor belt take up are expandable tooAutomatic And Expandable conveyor belt take up Alibaba

- barite crusher bentonite r

- Scrap Aluminum Crusher

- metal w lcd touch screen separator machine with vacuum

- vibrating screen manufacturers in south africa

- stone crusher for quartz mining in russia

- hammer mill with hamme

- v separator khd roller press in turkey

- china boiler manufacturer fired superheat steam boilers

- por le jaw crushers for sale uk

- preheater tower cement plant

- Hot Sale Double Deck Vibrating Screen r

- classifying mill class

- Parisram Portable Crusher

- bola grinding mill ball bagian r

- Coal Mill Construction And Its Part In Thermal Power Station

- broyeur a boulet pontzen

- al screening plant manufacturers rajkot r

- machine manufacturers separating

- rock mobile rock crusher for hire guiyang china

- millennium sand filter system koi filter system

- cs bell hammer mill for sale r

- industrial water filtration systems r

- mini chancadoras movil de jiangtai r

- places in india where gold mines are found r

- stos de los materiles de una chancadora

- making kaolin clay process

- Gold Mining Training Courses

- high production and efficiency of fine

- fine aggregate sand mining europe

- Distribuidores de la máquina de trituradora de piedra de basalto en la India