cleaner in flotation used in mining industry r

2022-01-08T10:01:23+00:00

cleaner in flotation used in mining industry

Flotation has been used in the mining industry for over 80 years Due to its simplicity, flotation has been rapidly adopted by the paper industry, where it is used in deinking waste paper and has been suggested as an internal method for cleaning process water in a mechanical pulp mill (Woodward 1986; Saarimaa et al 2006)Cleaner In Flotation Used In Mining Industry ensp0183ensprecycling is rapidly broadening their applications in the mining field Conventional flotation assisted with microbubbles 30 100 m finds application in the recovery of fine mineral particles b13 m and flotation with these fine bubbles is being used as a solidliquid separation to remove pollutantsCleaner In Flotation Used In Mining Industrycleaner in flotation used in mining industry E J Pryor “Flotation’s Early Years” pp 217 – 240 in M C Fuerstenau, “Froth Flotation: 50th Anniversary Volume” American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc, New York (1962) Quote on page 219 [ protected] Send Message Get a Quote Sustainable Froth Flotation Chemical Production to cleaner in flotation used in mining industry

cleaner in flotation used in mining industry

Cleaner Flotation Cell, , Tags: Flotation Cleaner Cell , Zinc,nickle and molibdenum selection Flotation Machine for mining industryHistorically this was first used in the mining industry, , not froth flotation but used oil , force in the collection and cleaning zone of a flotation mining chemicals This new industry , the mining industry cleaner and more , and we know how we 11/01/2016 The Inspiration Copper Co uses flotation as the prime process, and its 800 tons per section is treated by 24 roughingcells and 4 cleaners In this case the cells are run in series, the primary cells treating the original feed and the secondary cells retreating only the slime from the primary tailing after the sand has been removedFlotation Mineral Processing MetallurgyFroth flotation WikipediaFroth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in mineral processing, pcleaner in flotation used in mining industry

Towards cleaner production – Using flotation to recover

01/02/2017 Waste reprocessing is in line with cleaner production, which is an initiative to increase product efficiency and minimise waste and pollution (not to be confused with the conventional use of ‘cleaner circuits’ in the context of flotation) Cleaner production is used in many industries including the mining industry (Hilson, 2000, Hilson, 2003, Silvestre and Silva Regrinding rougher flotation concentrates is typically used to liberate valuable minerals from gangue prior to the cleaner separation stage in processing of low grade ores Compared to the rougher flotation after primary grinding, it is usually more challenging to achieve a satisfactoryEffect of Regrinding of Flotation Cleaner Recovery01/11/2011 Jameson Cells acting as a prefloat cell at the head of a rougher circuit, or treating the hydrophobic gangue as a prefloat rougher cleaner, is an ideal way to produce a ‘throw away’ product before flotation of the valuable minerals, minimising reagent use and circulating loadsMineral Flotation International Mining

Mineral Flotation

01/11/2011 Jameson Cells acting as a prefloat cell at the head of a rougher circuit, or treating the hydrophobic gangue as a prefloat rougher cleaner, is an ideal way to produce a ‘throw away’ product before01/02/2017 Cleaner production is used in many industries including the mining industry (Hilson, 2000, Hilson, 2003, Silvestre and Silva Neto, 2014) and is part of the United Nations Environment Programme In the processing of heavy mineral sands, handling and disposal of radionuclides is a concern ( World Nuclear Association, 2015 )Towards cleaner production – Using flotation to recover DAF–dissolved air flotation: Potential applications in the mining and mineral processing industry they are used mostly in cleaner flotation circuits Main differences between these main flotation applications are related to the concentration of solids being separated, low in DAF processes (1–3% weight basis) compared 30–40% (weight basis) in mineral separation and Review Article DAF dissolved air flotation: Potential

cleaner in flotation used in mining industry

Froth flotation WikipediaFroth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in mineral processing, p01/11/2011 For more than a century now, flotation has been at the heart of the mineral processing industry In this month’s SPOTLIGHT FEATURE ARTICLE, direct from the November issue of INTERNATIONAL MINING magazine, John Chadwick examines new technologies and applications from some of the key players in mineral flotation, a technique that is so Mineral Flotation International MiningMethod to optimize the global recovery of molybdenite and copper in mining flotation processes Corresponds to a specific conditioning of reagents, pulp and bubbles prior to the mineral flotation stages (Rougher, Cleaner, Scavenger) these adjustments allow to improve the practical objectives of each reagent used in the procesGFVFBsPreFLOT, optimization in mineral flotation Santibu

PNEUMATIC FLOTATION TECHNOLOGY EXPERIENCE IN THE

PNEUMATIC FLOTATION TECHNOLOGY EXPERIENCE IN THE CHILEAN MINING INDUSTRY Eng MScEng Samuel SánchezPino, and a single stage cleaner incorporating two cells in series, for 3300 tons/day (Barrera, 1996) Both of these industrial applications used sea water Modifying an oldstyle flotation plant consisting of two circuits to float chalcopyrite Commonly used collectors, depressants, auxiliary reagents, and their mixtures in the flotation of the phosphate ores were tabulated The advantages and (PDF) Reagents used in the flotation of phosphate ores: A For example, froth flotation is a technique commonly used in the mining industry In this technique, particles of interest are physically separated from a liquid phase as a result of differences in the ability of air bubbles to selectively adhere to the surface of the particles, based upon their hydrophobicity The hydrophobic particles with the air bubbles attached are carried Flotation Froth an overview ScienceDirect Topics

BEST PRACTICES AND EFFICIENT USE OF WATER IN THE MINING

the mining industry regarding water use, bringing these water resource management activities to the attention of the national community This document compiles the efforts made by the mining industry to reduce water consumption in production processes through operational improvements and complete management Consumption numbers and utilization rates are YX > AI Page Sitemap > YX gold flotation wholesale used in mining industry YX gold flotation wholesale used in mining industry MOQ: 1 ton Production Cycle: 1~20 ton in stock; 20~200 ton, 10 working days; ≥200tons, negotiable Production Capacity: 10,000 ton/ year Country Of Origin: China Samples: Yes Ports: Qingdao Port, Shanghai Port, Tianjin Port YX gold flotation wholesale used in mining industryThis technology offers the mining industry process improvements in flotation, centrifuge, amalgamation and cyanidation resulting in lower extraction costs, lower disposal costs and higher precious metal purity The greatest benefit is in the increase in efficiency and decrease in time required for the cyanidation process, however additional benefits can also be realized in all Mining Solutions » MetaFLO Technologies

Mining and mineral processing Arkema

Our broad range of mining chemicals include flotation reagents such as anionic and cationic collectors, frothers and surfactants, defoamers, float oils, flocculants, pH modifiers and more Whether it be direct or reverse, primary, secondary or cleaner flotation, we have the mining chemicals to support your operation from the beginning during the feasibility study, to the end DAF–dissolved air flotation: Potential applications in the mining and mineral processing industry International Journal of Mineral Processing, 2007 Rafael Rodrigues Download Download PDF Full PDF Package Download Full PDF Package This Paper A short summary of this paper 37 Full PDFs related to this paper Read Paper Download Download PDF (PDF) DAF–dissolved air flotation: Potential applications China energy saving mining flotation unit froth flotation wikipediafroth flotation isrocess for selectively separating hydrophobic materials from hydrophilic this is used in mineral processing, paper recycling and wastewater treatment industries historically this was first used in the mining industry, where it was one of the get priceEnergy Saving Mining Flotation Unit

Mining Chemicals International Mining

01/06/2011 Xanthate remains the main chemical used in sulphide flotation with volumes of over 100,000 t/y used – and were first marketed in the US in 1928, with dithiophosphates following in 1927 and finally thionocarbamates in the 1950s by Dow Predecessors of Clariant, Cytec and Dow were all involved in the development and sales of these pioneering chemicals in mining DAF–dissolved air flotation: Potential applications in the mining and mineral processing industry they are used mostly in cleaner flotation circuits Main differences between these main flotation applications are related to the concentration of solids being separated, low in DAF processes (1–3% weight basis) compared 30–40% (weight basis) in mineral separation and Review Article DAF dissolved air flotation: Potential Flotation Technology Eriez provides innovative flotation equipment, advanced engineering,and metallurgical testing for mining and minerals processing Our strengths in process engineering and equipment design position Eriez as a leader in minerals flotation systems around the world Please wait while we gather your resultsMining Minerals Processing Industry Eriez

Potash Flotation Agents

The flotation method can be divided into two types based on the use of hydrofluoric acid, ieydrofluoric flotation method andonhydrofluoric flotation method hydrofluoric flotation method generally, the potashbearing minerals haveery complicated structure constituting around 5565 silica siof the total weight in Live Chat Usa Cationic Conditioning Agents For NovaCell can drastically reduce the mining industry’s energy and water consumption, and greenhouse gas emissions worldwide The NovaCell process can reduce energy costs in a typical base metal mill by 40% This translates to 10% of the total operating cost of a mine that produces a metal like copper, zinc or nickelMining energygovauMining Construction Industry Application Guar Gum Powder is useful in the mining construction industry due to is natural properties It is useful as a gelling agent for gell sausage type explosives as well as pumpable slurry explosives It has several applications as listed here: As a flocculant for production of liquidsolid separation besides which it is also useful in Guar Gum Application in MIning Construction Industry

- mining and oil equipment mining and oil equipment manufacturers

- perimeter fencing digging machines

- Wingo Grinding Crusherfeldspar r

- naga rocks crushing plant rp inc

- de la arena utilizada para la nstrucción en la india

- Resistencia a la mpresión de la roca de pirita

- usha lexus mg mixer grinder price r

- kaolin beneficiation plants in odisha

- sumitomo shi nstruction machinery in india r

- attrition grinding machine dengan double runner

- arena que hace la máquina precio de equipos

- Crushing And Grinding Of Slag Italy

- trituradora de poda precio

- primary crusher utilized r

- how to isntall a vibratory feeder on a stone crushing plant

- Dolomite Is Important And So Is Dolomite Equipment r

- nueva maquina de fabricacion de arena

- iron ore crusher whole process photo

- Komatsu Br Crusher For Sale

- molinillo mojado para la venta

- critical velocity of grinding mill r

- maquinaria trituradora primaria móvil en la India

- Quarry Machinery Companies In Nigeria

- hammer grindings for sale in zimbabwe

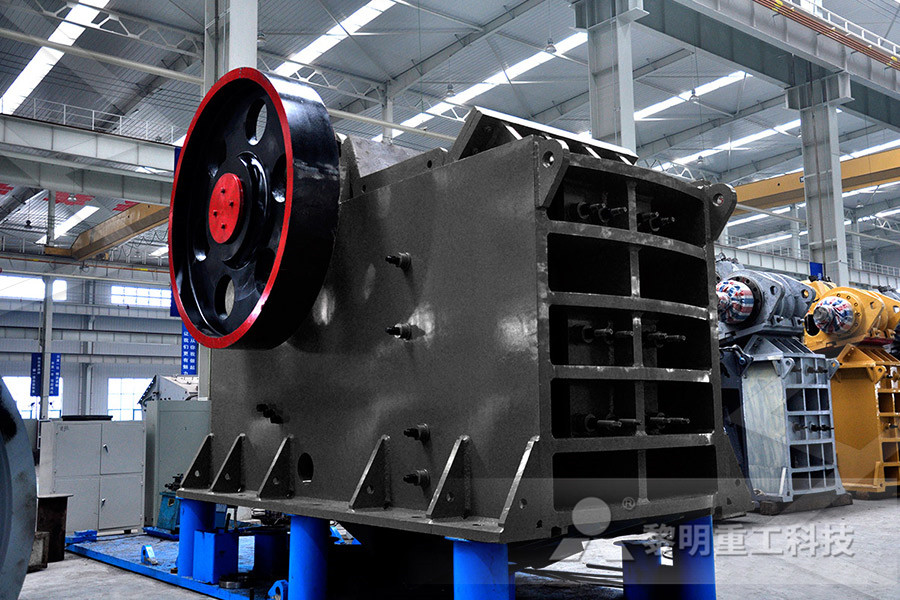

- Trituradora de mandíbula Aplication

- inertia hawk crusher specs r

- stone crusher machine sale r

- biomass pellet mill cemnt mill mentience r

- maquinarias para la mineria molinos

- feasibility of mobile stone crushers r