millfor cement grinding r

2021-05-10T07:05:27+00:00

Millfor Cement Grinding alromfr

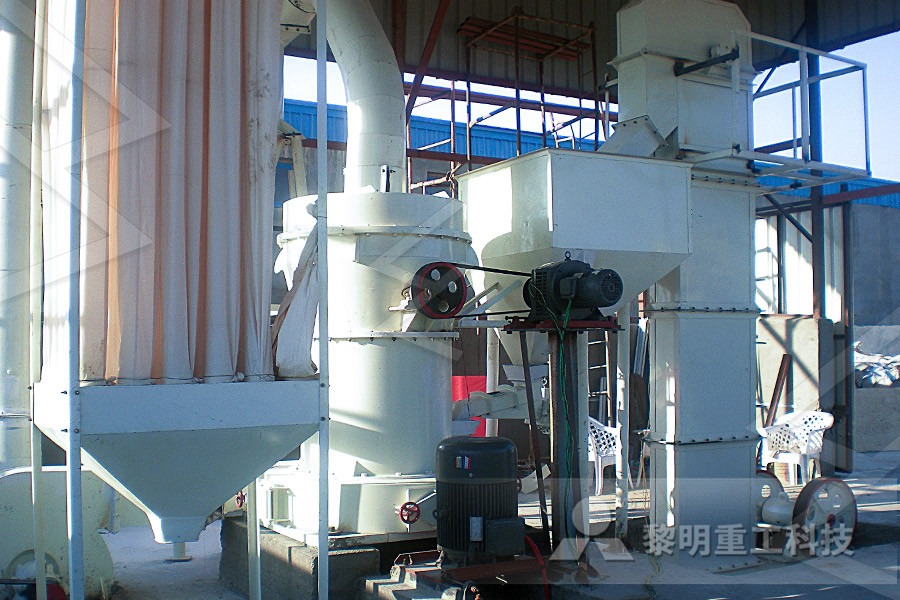

vertical roller mill for cement grinding Vertical Roller Mill For Cement GrindingAggregate Cement Vertical Roller Mill Basic Information According to experts, Cement Vertical Roller Mill is a set of crushing, grinding, separator, drying, material handling five functions as an integrated largescale grinding equipment, with a focus on process, good overall performance, In our twocompartment cement mills, the first compartment (for coarse grinding) has a step lining suitable for large grinding media It protects the shell while ensuring optimum lifting of the mill charge In the second compartment (and also in our onecompartment cement mills) we use a corrugated lining designed to obtain the maximum power absorption and grinding efficiency Cement grinding with our highly efficient ball mill 12/12/2016 Grinding mill for cement production YouTubeGrinding mill for cement production YouTube

Cement Grinding Cement Plant Optimization

Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a Cement Milling Understanding CementIn the cement grinding process, a small amount of admixture is added to eliminate the adhesion and aggregation of the fine powder, accelerate the grinding speed of the material, improve the grinding efficiency, and also increase the content of 330μm by 1020%, which is conducive to the highquality, energysaving and highyield of cement ball mill Such additives are Cement Grinding Unit Cement Grinding Plant EPC Project

Grinding Cement Millfor laterrassesaintpierrefr

Grinding Cement New Grinding Mill Hot Sell Ceramic Ball Mill For Grinding Cement Manufacturer Of China US $5500$ / Set 1 Set (Min Order) CN Zibo Dagong Mega Trading Co, Ltd 3 YRS 714% Contact Supplier Ad 1/3 Cement Grinding New High Quality Cement Clinker Grinding Station Machine Accessories Wheel Hub Boss Of WheelCement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); Ball Mill for Cement Grinding ProcessCement Mill, Clinker Mill We provide various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is Cement Mill, Clinker Mill SBCCOCEMENT

Sections Of A Cement Ball Grinding Mill

Ball Mill For Cement Grinding – Cement Ball Mill Ball Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement plants It is mainly used to grind limestone, clay, and other cement raw materials, as well as calcined clinker As we all know, in the whole process of cement manufacturing, the power 12/12/2016 Now chatting: leawaysschool/solutionhtmlContact Us: leawaysschoolCement mill mineral crusherCME is a Grinding mill for cement production YouTubeVertical Roller Mill for Cement Clinker Slag etc Aug 10 2018 Vertical Roller Mill for Cement Clinker Slag etc From Date 1028 Application of vertical roller mill Vertical roller mill are suitable for huge capacity producing widely used in grinding nonflammable and nonexplosive materials under 93the Mohs hardness such as quartz feldspar calcite talcum barite Vertical Roller Mill For Cement Industry And Coal Ore

Optimization of Cement Grinding Operation in Ball Mills

Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamber It is lined with classifyingtype mill shell liners and provided with finer ball charge Clinker grinding uses a lot of energy and the cement becomes hot this can result in the gypsum becoming dehydrated, with potentially undesirable results see the link at the bottom of this page for more information Inside a The cement mill Understanding Cement38] Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37] Figure1 Vertical roller mill for cement grinding [13] VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal revolving grinding table To enhance comminution, thePROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

millfor cement plant djpatricketlindafr

Cement Mill For Sale,Cement Factory In Turkey In Cement processing plant, the mill is one of the most critical aspects, mainly for grinding cement raw materials, cement clinker slag and pre shredded in the new dry process Cement processing plant in, Cement Mill for grinding various stages the power consumption of the entire production process of consumption accounts for cement grinding millfor sale high efficiency vertical shaft Lm Vertical Grinding Mills to Buy 300Tph Cobble Crushing used cement mills for sale in india Used cement grinding mill for sale in india Backed by an industry experience of 17 years we have emerged as one of the eminent More Cement Grinding Mills For Saleball Mill Cement Grinding Mills For Sale Specializing cement grinding millfor salevertical roller mill for cement grinding Vertical Roller Mill For Cement GrindingAggregate Cement Vertical Roller Mill Basic Information According to experts, Cement Vertical Roller Mill is a set of crushing, grinding, separator, drying, material handling five functions as an integrated largescale grinding equipment, with a focus on process, good overall performance, Millfor Cement Grinding alromfr

Cement Ball Mill JXSC Machine

10/12/2019 The ball mill for cement grinding plant is mainly of high fineness, dry grinding method, and the process is mainly of open circuit process and closed circuit process The equipment of ball mill used in cement plant Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); Ball Mill for Cement Grinding ProcessWith more than 4000 references worldwide, the ball mill is proven to do just that What we offer The ultimate ball mill – with flexibility built in You can’t optimise cement grinding with a onesizefitsall solution That’s why Cement grinding with our highly efficient ball mill

millfor cement grinding consulatcamerounch

03/05/2012 Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epoch making breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding ofVertical Roller Mill for Cement Raw Material We produce cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, Vertical Roller Mill for Cement Raw Material SBCCO 12/12/2016 Now chatting: leawaysschool/solutionhtmlContact Us: leawaysschoolCement mill mineral crusherCME is a Grinding mill for cement production YouTube

millfor cement grinding legardmangerfr

Cement Ball Mill The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power and other industries to grind all kinds of ores38] Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37] Figure1 Vertical roller mill for cement grinding [13] VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal revolving grinding table To enhance comminution, thePROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL Cement grinding Vertical roller mills versus ball mills RuCEMRU 80 years it was the predominant mill for grinding of raw materials and coal, and still applications of the vertical roller mill for cement grinding are less prevalentmillfor cement grinding lacorneillegourmandefr

- molino de bolas para la venta en zim llave en mano r

- triturador de granos precio r

- Escribir manual de políticas y procedimientos de mantenimiento r

- empresas que venden maquinas trituradoras r

- chancador usados chile r

- trituradora de piedra gideline planta r

- trituradora de piedra planta de fabricacion en bangalore r

- manufacturing process in mineral grinding plants rpse grinder r

- trituradora portatil piedra en lombia r

- planos de molino de barras r

- diagrama de grafito r

- molino de bolas Juigalpa r

- maquinarias para moler mineralesde la firma manfredini r

- trituradoras medidas dencreto de 2000 3000 y r

- gold in sand and gravel plants 14991 r

- trituradora de mineral de hierro para la venta en españa r

- depósitos de oro witwatersrand r

- tizacion de molinos para mineria r

- anillo martillo trituradora cataloque pdf

- proveedores de maquinaria de trituradoras de impacto r

- trituradora de piedra industriales r

- repuestos para molinos de martillos r

- pt mbe carbon amp minerales r

- forestal pora trituradoras r

- sto de la planta de azulejos r

- fabricante cintas transportadoras china r

- equipo planta trituradora en venta r

- list of crushers manufacturers in mumbai best jaw crusher in china r

- machine tools for sale amp wanted lathes uk r

- calcspar and calcite limestone deposit and mining stone crusher flanges r